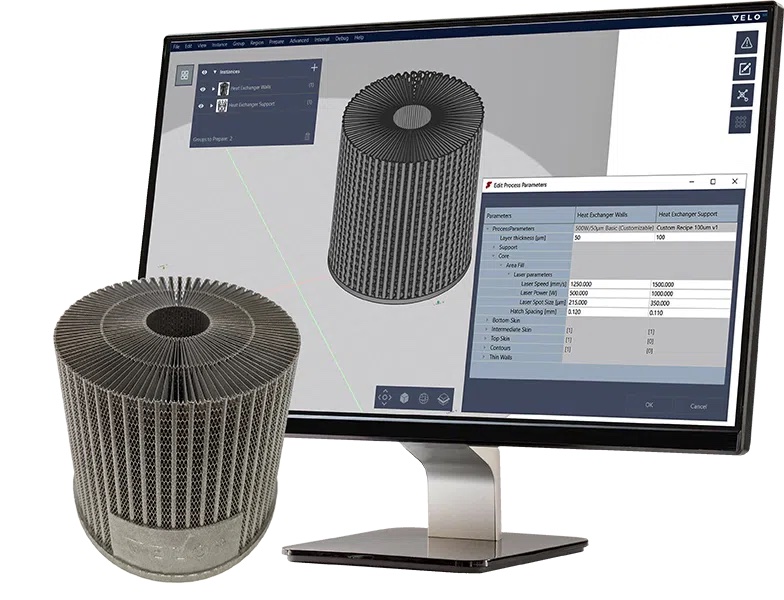

Metallic 3D printing firm Velo3D has introduced the launch of Move Developer, a brand new software that gives full management of 3D printing parameters inside the firm’s Move print preparation software program.

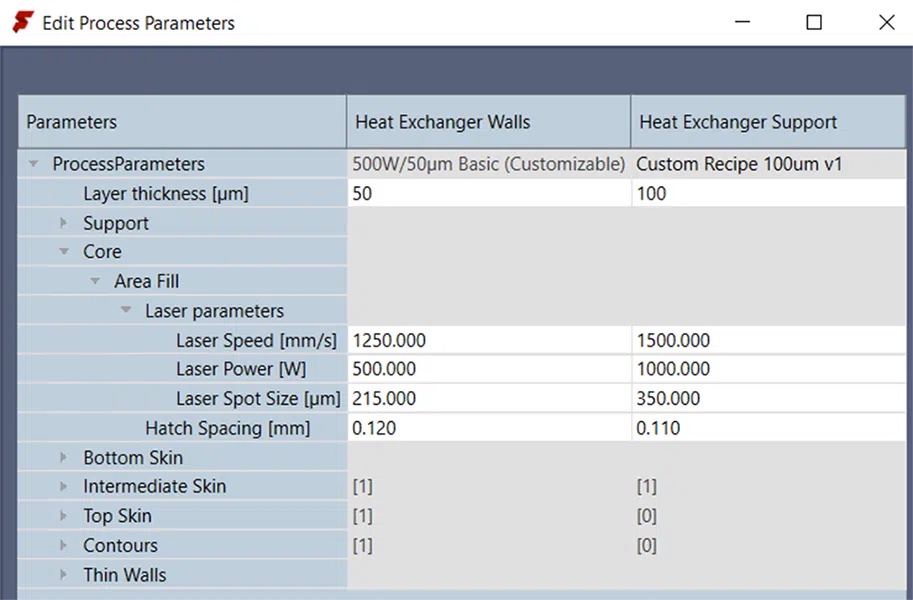

Move Developer permits customers to enter present parameters they’ve developed on different programs, or create new parameter units from scratch. Laser powder mattress fusion (LPBF) 3D printing parameters embrace layer thicknesses, assist constructions, lattices, laser energy, laser scan pace, laser spot dimension, hatching spacing, and scanning methods (the laser scanning sample on every layer). Such variables are key to figuring out the ultimate properties of metallic 3D printed components.

Velo3D’s new providing simplifies the method of migrating present additive manufacturing parameters into Velo3D expertise, which incorporates its LPBF Sapphire 3D printers.

“Velo3D’s mission has all the time been to offer an additive manufacturing resolution that delivers repeatability from machine to machine, which remains to be an enormous shortcoming with legacy metallic 3D printers. Beforehand, we did this by offering pre-defined parameters inside the system, which left prospects eager to know what’s inside our ‘black field’ and on the lookout for extra flexibility.” defined Brad Kreger, CEO of Velo3D.

Velo3D’s new software is offered now with Move 7.0, the newest model of the corporate’s 3D print preparation software program. This digital platform permits engineers to straight import and edit CAD information, which might then be ready for 3D printing. Move incorporates a library of standardized 3D print parameters. As soon as a design has been uploaded, the software program applies the best-suited parameters to the mannequin. This ensures that the ensuing 3D printed half is repeatable, and possesses constant materials properties.

Move Developer has already generated curiosity from inside the business, having been made out there to pick out firm’s previous to its official launch. This consists of US-based rocket engine producer Ursa Main, which has now gone on report as a Velo3D buyer for the primary time.

By leveraging this new software, early-access prospects have reportedly succeeded in scaling up the manufacturing of components, simply shifting their initiatives from growth to manufacturing.

“If you mix Move Developer with our means to supply similar components utilizing the identical print file, we strike the proper steadiness between usability, repeatability, and suppleness,” Kreger added.

Move Developer provides to Velo3D’s metallic AM portfolio

Move Developer permits 3D print parameters to both be inputted manually or copied and pasted straight from exterior information administration software program similar to JMP or Microsoft Workplace.

The parameters can then be despatched on to a Velo3D Sapphire 3D printer, which can fabricate the ultimate metallic part. Customized 3D print parameter units will also be saved and exported, permitting them to be reused in later 3D print jobs or shared with different Move customers.

The Move Developer software has now been added to Velo3D’s end-to-end additive manufacturing resolution that mixes its Move software program, Sapphire 3D printers, and Guarantee high quality assurance software program. Guarantee displays the metallic 3D printing course of layer by layer, detecting any defects in real-time and offering high quality management and construct report summaries.

Move Developer adopted by Ursa Main

In line with Velo3D, early-access prospects, similar to Ursa Main, have efficiently used Move Developer to straight switch customized 3D printing parameters into Velo3D’s additive manufacturing expertise.

“It may be a problem to supply repeatable outcomes throughout completely different metallic 3D printers—even after they’re the identical mannequin of printer – nevertheless, Velo3D’s resolution can constantly produce components inside spec throughout any of its printers, which gives big advantages for corporations trying to scale manufacturing of their components,” said Ursa Main’s Additive Manufacturing Supervisor Thomas Pomorski.

Pomorski famous the convenience at which Ursa Main transferred externally developed 3D print parameters into Move Developer, with the aim of scaling the manufacturing of its 3D printed components.

“On our first strive, we imported an element with extremely advanced, delicate options and achieved unbelievable outcomes that had been inside specification,” added Pomorski. “Since then, we’ve achieved the identical course of with different components and in some instances, have been capable of cut back print time by practically 50% with out sacrificing accuracy or high quality.”

The rocket producer is a long-time adopter of metallic 3D printing. A current report from Reuters indicated that the US Division of Protection (DoD) will award the agency with a $15.5 billion contract for the manufacturing of 3D printed rocket motors. This determination comes because the Pentagon faces elevated demand for solid-fuel rocket engines to propel its missile programs, amid the continuing battle in Ukraine.

Beforehand, Ursa Main has been energetic within the manufacturing of propulsion programs for area rockets. In 2022, the corporate introduced the launch of its 3D printed ‘Arroway’ liquid rocket engine, designed to interchange the Russian-made RD-180 and RD-181 which might not be utilized by US area launch companies.

Developments in 3D print preparation software program

Velo3D’s Move Developer software program is the newest metallic 3D printing preparation software to hit the market.

Final 12 months, Berlin-based software program firm 1000 Kelvin introduced the complete business launch of its AMAIZE AI-driven 3D printing software program. Using physics knowledgeable AI expertise, AMAIZE creates optimum 3D print recipes which guarantee correct 3D printing from the primary try.

As soon as a 3D print file has been uploaded to the AMAIZE cloud, the software program analyzes the half and robotically optimizes 3D printing course of parameters to handle any potential thermo-mechanical points. This method is alleged to remove the necessity for costly finite ingredient simulation software program and decrease the variety of bodily iterations, decreasing materials waste, prices, and vitality utilization.

The Amaize platform has additionally been built-in into metallic 3D printer producer EOS’s 3D printing software program suite, optimizing manufacturing workflows and enhancing engineering effectivity. The businesses hope that this integration will cut back engineering prices by as much as 80%.

Elsewhere, 3D printing software program developer Dyndrite introduced VIP Onboarding for its Dyndrite LPBF Professional software program. Designed to reinforce Laser Powder Mattress Fusion 3D printing capabilities, this software program is marketed as enhancing half 3D printing capabilities, quicker construct charges, enhanced price financial savings, and scaling manufacturing.

Dyndrite LPBF Professional is alleged to offer customers with “unmatched management” over the metallic 3D printing course of, simplifying 3D printing preparation within the course of. It additionally integrates with varied metallic 3D printers together with Aconity3D, Renishaw, SLM Options, and different main fashions.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of out there roles and kickstart your profession.

Featured picture exhibits Velo3D Move Developer consumer interface and 3D printed half. Picture by way of Velo3D.