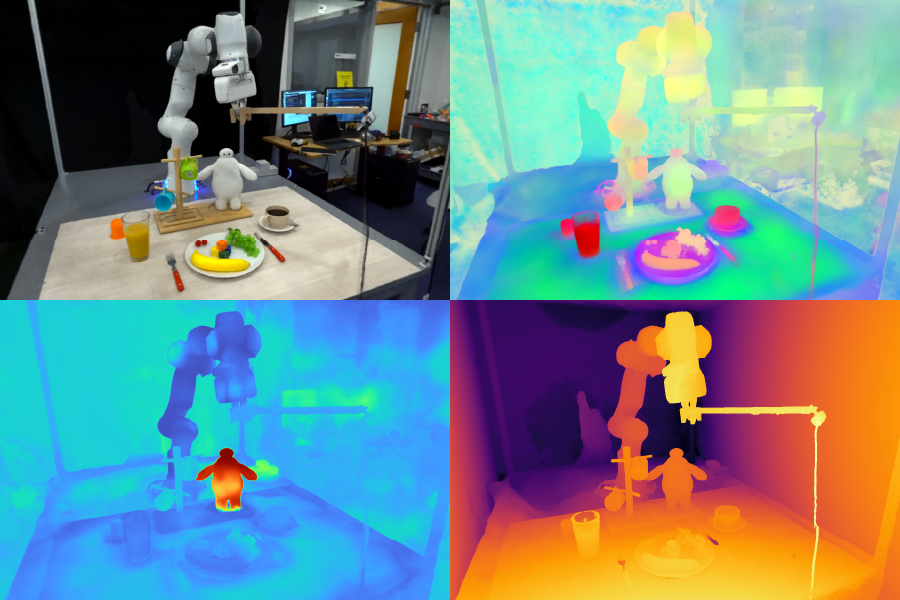

Function Fields for Robotic Manipulation (F3RM) permits robots to interpret open-ended textual content prompts utilizing pure language, serving to the machines manipulate unfamiliar objects. The system’s 3D function fields might be useful in environments that include 1000’s of objects, comparable to warehouses. Photographs courtesy of the researchers.

By Alex Shipps | MIT CSAIL

Think about you’re visiting a good friend overseas, and also you look inside their fridge to see what would make for a terrific breakfast. Most of the gadgets initially seem overseas to you, with every one encased in unfamiliar packaging and containers. Regardless of these visible distinctions, you start to know what every one is used for and choose them up as wanted.

Impressed by people’ means to deal with unfamiliar objects, a gaggle from MIT’s Pc Science and Synthetic Intelligence Laboratory (CSAIL) designed Function Fields for Robotic Manipulation (F3RM), a system that blends 2D pictures with basis mannequin options into 3D scenes to assist robots determine and grasp close by gadgets. F3RM can interpret open-ended language prompts from people, making the strategy useful in real-world environments that include 1000’s of objects, like warehouses and households.

F3RM affords robots the power to interpret open-ended textual content prompts utilizing pure language, serving to the machines manipulate objects. In consequence, the machines can perceive less-specific requests from people and nonetheless full the specified job. For instance, if a consumer asks the robotic to “choose up a tall mug,” the robotic can find and seize the merchandise that most closely fits that description.

“Making robots that may really generalize in the actual world is extremely laborious,” says Ge Yang, postdoc on the Nationwide Science Basis AI Institute for Synthetic Intelligence and Basic Interactions and MIT CSAIL. “We actually wish to determine how to do this, so with this challenge, we attempt to push for an aggressive stage of generalization, from simply three or 4 objects to something we discover in MIT’s Stata Heart. We needed to learn to make robots as versatile as ourselves, since we will grasp and place objects although we’ve by no means seen them earlier than.”

Studying “what’s the place by trying”

The strategy may help robots with choosing gadgets in giant achievement facilities with inevitable muddle and unpredictability. In these warehouses, robots are sometimes given an outline of the stock that they’re required to determine. The robots should match the textual content offered to an object, no matter variations in packaging, in order that clients’ orders are shipped accurately.

For instance, the achievement facilities of main on-line retailers can include hundreds of thousands of things, a lot of which a robotic can have by no means encountered earlier than. To function at such a scale, robots want to know the geometry and semantics of various gadgets, with some being in tight areas. With F3RM’s superior spatial and semantic notion talents, a robotic may change into simpler at finding an object, inserting it in a bin, after which sending it alongside for packaging. In the end, this could assist manufacturing unit staff ship clients’ orders extra effectively.

“One factor that usually surprises folks with F3RM is that the identical system additionally works on a room and constructing scale, and can be utilized to construct simulation environments for robotic studying and enormous maps,” says Yang. “However earlier than we scale up this work additional, we wish to first make this technique work actually quick. This fashion, we will use such a illustration for extra dynamic robotic management duties, hopefully in real-time, in order that robots that deal with extra dynamic duties can use it for notion.”

The MIT crew notes that F3RM’s means to know completely different scenes may make it helpful in city and family environments. For instance, the strategy may assist personalised robots determine and choose up particular gadgets. The system aids robots in greedy their environment — each bodily and perceptively.

“Visible notion was outlined by David Marr as the issue of understanding ‘what’s the place by trying,’” says senior creator Phillip Isola, MIT affiliate professor {of electrical} engineering and pc science and CSAIL principal investigator. “Latest basis fashions have gotten actually good at understanding what they’re ; they’ll acknowledge 1000’s of object classes and supply detailed textual content descriptions of pictures. On the identical time, radiance fields have gotten actually good at representing the place stuff is in a scene. The mix of those two approaches can create a illustration of what’s the place in 3D, and what our work exhibits is that this mixture is very helpful for robotic duties, which require manipulating objects in 3D.”

Making a “digital twin”

F3RM begins to know its environment by taking footage on a selfie stick. The mounted digicam snaps 50 pictures at completely different poses, enabling it to construct a neural radiance discipline (NeRF), a deep studying technique that takes 2D pictures to assemble a 3D scene. This collage of RGB images creates a “digital twin” of its environment within the type of a 360-degree illustration of what’s close by.

Along with a extremely detailed neural radiance discipline, F3RM additionally builds a function discipline to enhance geometry with semantic info. The system makes use of CLIP, a imaginative and prescient basis mannequin educated on lots of of hundreds of thousands of pictures to effectively study visible ideas. By reconstructing the 2D CLIP options for the photographs taken by the selfie stick, F3RM successfully lifts the 2D options right into a 3D illustration.

Holding issues open-ended

After receiving just a few demonstrations, the robotic applies what it is aware of about geometry and semantics to know objects it has by no means encountered earlier than. As soon as a consumer submits a textual content question, the robotic searches via the house of attainable grasps to determine these most probably to reach choosing up the item requested by the consumer. Every potential choice is scored primarily based on its relevance to the immediate, similarity to the demonstrations the robotic has been educated on, and if it causes any collisions. The best-scored grasp is then chosen and executed.

To exhibit the system’s means to interpret open-ended requests from people, the researchers prompted the robotic to select up Baymax, a personality from Disney’s “Large Hero 6.” Whereas F3RM had by no means been instantly educated to select up a toy of the cartoon superhero, the robotic used its spatial consciousness and vision-language options from the muse fashions to determine which object to know and methods to choose it up.

F3RM additionally permits customers to specify which object they need the robotic to deal with at completely different ranges of linguistic element. For instance, if there’s a steel mug and a glass mug, the consumer can ask the robotic for the “glass mug.” If the bot sees two glass mugs and one in all them is crammed with espresso and the opposite with juice, the consumer can ask for the “glass mug with espresso.” The inspiration mannequin options embedded inside the function discipline allow this stage of open-ended understanding.

“If I confirmed an individual methods to choose up a mug by the lip, they may simply switch that data to select up objects with comparable geometries comparable to bowls, measuring beakers, and even rolls of tape. For robots, attaining this stage of adaptability has been fairly difficult,” says MIT PhD pupil, CSAIL affiliate, and co-lead creator William Shen. “F3RM combines geometric understanding with semantics from basis fashions educated on internet-scale information to allow this stage of aggressive generalization from only a small variety of demonstrations.”

Shen and Yang wrote the paper below the supervision of Isola, with MIT professor and CSAIL principal investigator Leslie Pack Kaelbling and undergraduate college students Alan Yu and Jansen Wong as co-authors. The crew was supported, partly, by Amazon.com Providers, the Nationwide Science Basis, the Air Power Workplace of Scientific Analysis, the Workplace of Naval Analysis’s Multidisciplinary College Initiative, the Military Analysis Workplace, the MIT-IBM Watson Lab, and the MIT Quest for Intelligence. Their work will likely be offered on the 2023 Convention on Robotic Studying.

MIT Information