The Harmonic Drive is a key a part of numerous robotic purposes. Extremely easy but fairly odd to observe, this gear system is extraordinarily exact with a powerful torque-to-weight ratio, even when it does wobble. So how does it work?

The seemingly weird Harmonic Drive gear is definitely quite genius in the way it features – its flexible-ellipse-within-a-circle setup creates a wobbling movement because it turns, and locations solely a couple of third of its two foremost gears’ enamel involved with one another at any given level – however the result’s a remarkably compact and lightwight little drive gear able to delivering glorious torque with absolute precision, and 0 drive lash or free play.

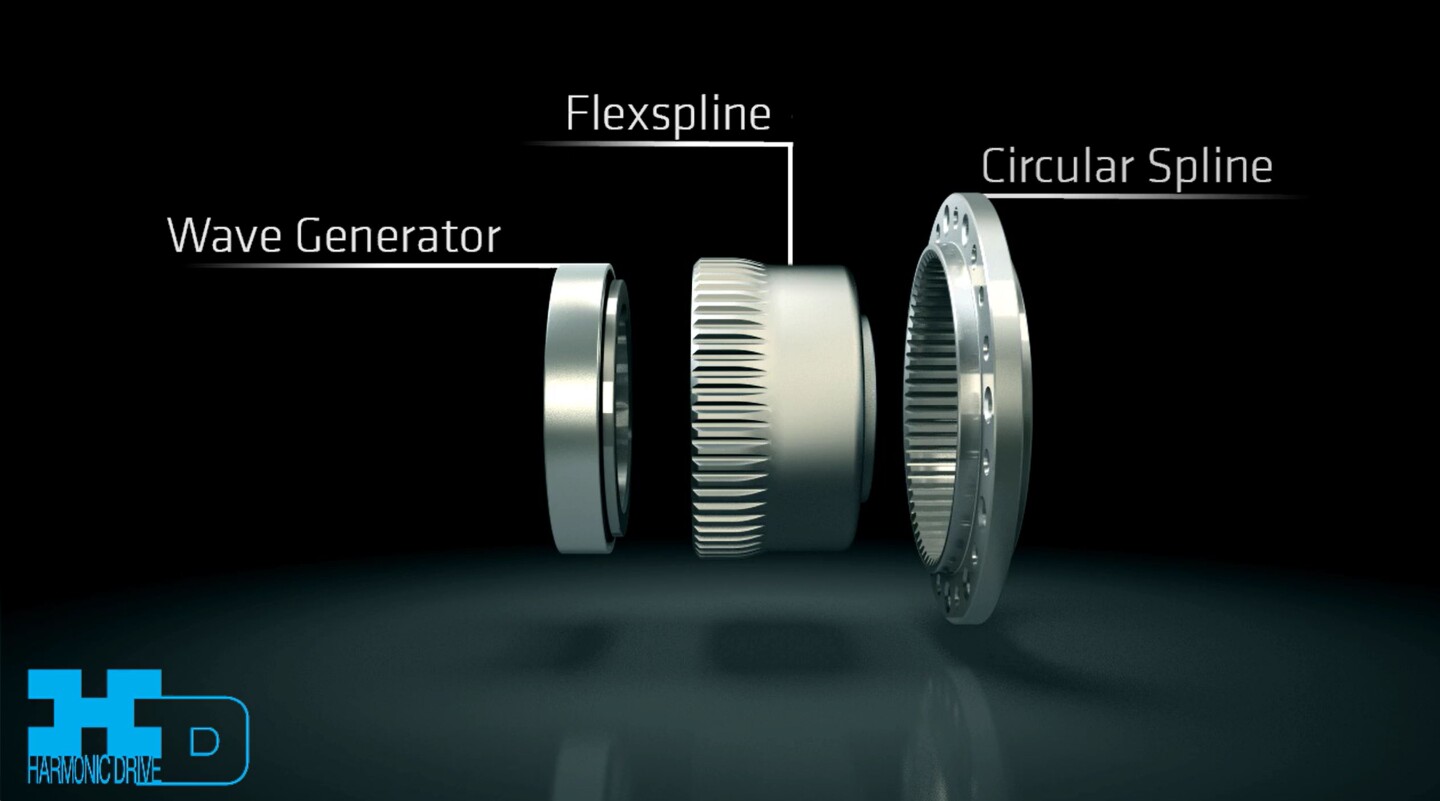

It was first conceived in 1957 by Pennsylvania’s C. Walton Musser, a splendidly artistic inventor with patents on every part from energy steering programs, recoilless rifles and pneumatic life jacket inflators, by means of to many key concepts underpinning jet plane ejection seats. The Harmonic Drive was first commercialized by the early Nineteen Sixties. It is made from three key parts:

Harmonic Drive

- The wave generator: A barely elliptical enter hub with a ball bearing race round its periphery.

- The flexspline: A versatile, cup-shaped element with enamel on its outer perimeter. It deforms radially however retains torsional rigidity when the rectangular wave generator is inserted.

- The round spline: A very inflexible ring with inside enamel, just like a planetary ring gear, and with two extra enamel than the flexspline.

When the wave generator spins, about 30% of the flexspline’s enamel on both finish make contact with the round spline’s enamel at any given time, forming an advancing wave sample. This causes the flexspline to rotate throughout the round spline, however in the other way of the enter. Test it out:

Harmonic Drive® Pressure Wave Gear: Practical Precept | The Unique

A part of this method’s genius is its zero backlash – there is not any play between the gears, making it best for exact, superb motor management. Its compact, light-weight design can also be excellent for purposes with restricted house. And with few transferring components, the Harmonic Drive is very dependable and sturdy.

Right now, Harmonic Drives are in every single place on and off planet. Industrial robots like these from Fanuc and Common Robots use them for duties comparable to welding and meeting, the place repeatable, exact movement is crucial.

The da Vinci surgical robotic, designed for minimally invasive procedures, depends on Harmonic Drives in its arms, giving it delicate micro-movements with zero backlash for the utmost precision whereas performing minimally invasive operations on folks.

Harmonic Drive

Boston Dynamics’ Atlas humanoid and Spot Quadruped robots use them of their legs and arms, amongst different locations, to attain clean, managed movement whereas nonetheless being robust.

Even NASA’s Mars rovers, Curiosity and Perseverance, characteristic Harmonic Drives of their robotic arms and wheels. Sending rovers to a different planet with no hope of upkeep or restore stops is a testomony to the reliability and sturdiness of this design.

Whereas Musser by no means lived to see his invention attain Mars, he did at the least witness it go to house. The Harmonic Drive was widespread element within the Area Shuttle’s standard-issue Distant Manipulator System – aka “Canadarm” – used on shuttles like Columbia and Challenger to deal with payloads and deploy cargo.

Practically 70 years after its creation, this outstanding invention, with its distinctive but purposeful “wobble,” continues to be discovered throughout numerous fields. From exact surgical actions to the exploration of distant planets, the Harmonic Drive’s genius lies in its simplicity, reliability, and precision.

Harmonic Drive® pressure wave gear – zero backlash

Supply: Harmonic Drive