The final time I posted a Tiny Whoop DIY construct information was eight years in the past! Since then, the FPV world has seen spectacular developments, and now you don’t essentially have to construct your individual Tiny Whoop. Bind and Fly (BNF) fashions carry out brilliantly out of the field and are sometimes cheaper than constructing your individual. Nonetheless, constructing a Tiny Whoop from scratch continues to be a improbable solution to study the fundamentals of FPV drones, perceive how every part connects, and it may be a enjoyable challenge. On this tutorial, I’ll information you thru an inexpensive, extraordinarily excessive efficiency Tiny Whoop construct. We’ll go over the important elements, meeting course of, and a few helpful tricks to make your first construct a hit.

Why Construct a Tiny Whoop?

When you’re desirous about studying how one can construct a Tiny Whoop and dive into the world of FPV drones, Tiny Whoops are a wonderful place to begin. Constructing a light-weight Tiny Whoop is enjoyable, rewarding, and quite a bit much less intimidating for newbies—particularly in case you’re new to FPV drone flying.

These micro drones are inexpensive, compact, and light-weight, making them a lot safer to fly than bigger drones like a 5-inch quad. Since they’re designed to face up to crashes with out inflicting harm, they’re perfect for brand spanking new pilots who need to apply flying with out worry.

This construct minimizes soldering, preserving it easy for newbies. For this Tiny Whoop, you’ll solely have to solder the motors to the flight controller—simply three pads per motor. The remainder is plug-and-play, making it an ideal challenge in case you’re new to soldering or need to hold issues easy.

Components

The aim for this Tiny Whoop construct is to maintain the overall weight beneath 17 grams, leading to a strong and nimble micro drone. Attaining that is no simple feat—the lightest Tiny Whoop available on the market is simply over 17g, so staying beneath this weight requires cautious planning and exact execution.

For comparability, the Mobula6 2024 (proper) weighs 17.7g, the Air65 (center) weighs 17.2g, and my customized construct (left) solely weighs 16.8g.

The elements chosen are cutting-edge, providing efficiency that you just gained’t discover in an off-the-shelf whoop. Right here’s what you’ll have to construct a Tiny Whoop for round $130:

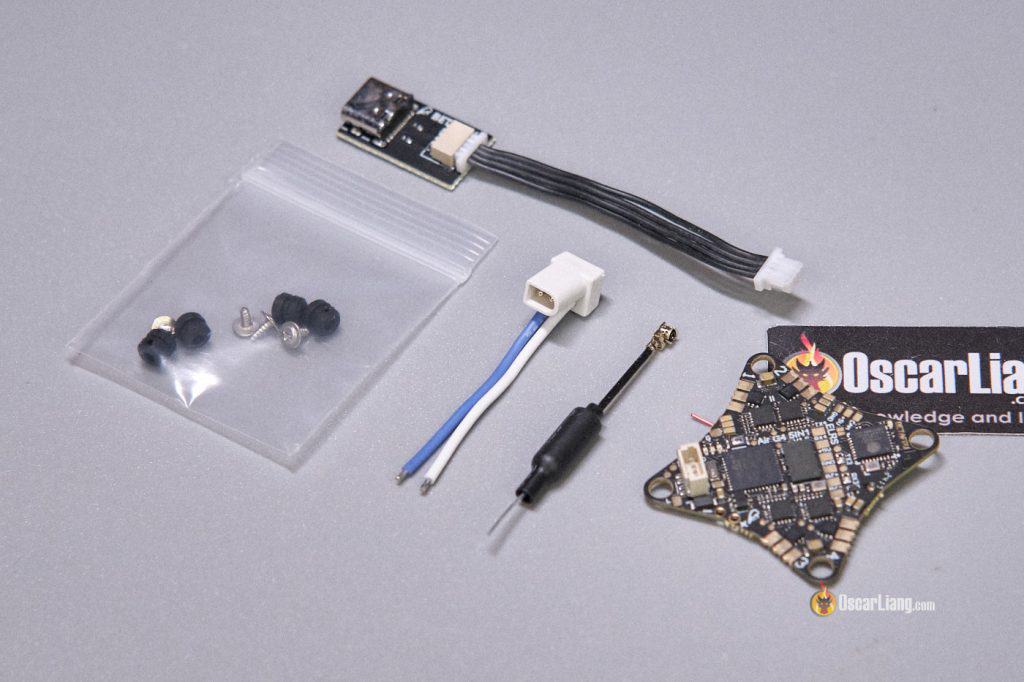

- FC / VTX / RX / 4in1 ESC: BetaFPV Air 5-in-1 AIO FC ($50)

- Motors: 4x BetaFPV 0702 30000KV ($49)

- FPV digital camera: BetaFPV CO3 digital camera ($20)

- Body: NewBeeDrone Cockroach LiteAF ($5)

- Cover: BetaFPV Micro Air Cover ($3)

- Propellers: HQ Ultralight Triblade ($2.5)

Constructing your individual tiny whoop might be dearer than a pre-built mannequin, and also you’ll have to assemble it your self. When you’re on the lookout for a ready-to-fly expertise, the BNF mannequin is a superb selection, listed here are my suggestions: https://oscarliang.com/best-tiny-whoop/#Greatest-65mm-Tiny-Whoops. However in case you’re after the satisfaction of constructing your individual micro drone with top-notch efficiency, this information is ideal for you.

BetaFPV Air 5in1 AIO Board

The star of this construct is the BetaFPV Air 5in1 AIO board, which is an absolute game-changer. Weighing solely 4.9g, this board integrates the flight controller, ESC, OSD, VTX, and ExpressLRS receiver into one light-weight unit. This setup not solely simplifies the construct but additionally reduces weight considerably. A 4in1 model with out a receiver can be accessible, however I like to recommend the 5in1 model except you intend to make use of a special receiver just like the TBS Crossfire Nano.

Get it right here:

BetaFPV 0702 30000KV

For this construct, I selected BetaFPV’s newest 0702 30,000KV motors. These high-KV motors shine in ultra-light builds, providing unimaginable responsiveness and pace. Decrease-KV variations, like 27000KV or 23000KV, can provide higher flight time, however in ultra-light builds, they have a tendency to really feel much less highly effective – this was notably noticeable once I was testing them again to again. The upper-KV motors additionally provide extra flexibility, as you may regulate motor output or scale down throttle in Betaflight in case you favor a slower, extra managed flight expertise. I’ve a tutorial explaining how one can scale down throttle right here: https://oscarliang.com/reduce-power-throttle-taranis-betaflight/.

Get it right here:

NewBeeDrone Cockroach LiteAF Body

The NewBeeDrone LiteAF body, weighing solely 2.4g, is at present the lightest body available on the market.

Get it right here:

The BetaFPV Meteor65 Air body is a superb various, used within the Air65 mannequin, and weighs barely extra at 2.8g with barely larger sturdiness. Get it from BetaFPV: https://oscarliang.com/product-d2cs

BetaFPV Air Cover

I selected the BetaFPV Air Cover for its compatibility with the digital camera we’re going to use. It’s easy, efficient, and light-weight, matching nicely with the remainder of the elements on this construct.

Get it right here:

BetaFPV CO3

For video, I opted for the BetaFPV CO3 analog digital camera, which supplies an important stability between picture element and area of view. It comes with a connector, which you’ll plug straight into the BetaFPV AIO board with none soldering, making meeting easy.

Get it right here:

HQ Ultralight Triblade

These HQ Ultralight Triblade props are perfect for high-KV 0702 motors (just like the 30000KV we’re utilizing) resulting from their light-weight design (about 0.5g per 4 props). They require much less torque to spin, offering an important stability between efficiency and sturdiness. One other in style choice is the Gemfan 1219S (about 0.8g per 4 props), which is barely extra sturdy however a bit heavier. Each are glorious selections for a 65mm Tiny Whoop construct.

Get it right here:

Different Parts

To fly this Tiny Whoop, you’ll want just a few further components and items of kit.

Listed below are my suggestions:

For extra Tiny Whoop-related equipment, try this publish: https://oscarliang.com/best-tiny-whoop/

The Construct Course of

Getting ready the FC

Solder the BT2.0 battery result in the ability pads on the flight controller (FC), paying cautious consideration to polarity—the blue wire is + (optimistic), and the white wire is – (damaging).

Getting ready the Motors

In case your motors include connectors, you’ll want to chop them off, leaving about 28-29mm of wire from the motor base. Dry-fit the motor and FC to double-check the mandatory wire size.

Be aware to not reduce off an excessive amount of wire, as this might put extra stress on the solder joints afterward. Ideally, depart a little bit of slack. If there’s an excessive amount of slack, you may twist the wires to stop them from dangling or interfering with the spinning propellers.

Some whoop FC comes with motor connectors, you may simply plug the motors in with out soldering. Nonetheless these add weight and introduce extra electrical resistance than direct soldering. For optimum efficiency, direct soldering is most well-liked.

Strip a little bit of insulation from the ends of the wires and tin them with contemporary solder.

Soldering the Motors

Tin the motor pads on the flight controller and apply a small quantity of solder flux to those pads, able to be soldered.

Solder the motor wires to the motor pads on the board. These pads are small, so a gentle hand and persistence are wanted, particularly in case you’re new to soldering. Work rapidly to keep away from overheating the pads, as this might trigger them to raise and completely broken.

The particular order of the wires doesn’t matter, as you may regulate motor rotation course later in software program.

New to soldering? Try this primary information: https://oscarliang.com/soldering-guide/

Mounting the FC

Insert the rubber grommets within the 4 nook holes of the FC.

Drop the FC into the body, guaranteeing the right orientation—often indicated by an arrow pointing ahead, with the battery connection on the again.

Mounting the Motors

Set up the motors on the body with the offered screws. They arrive with two sorts, steel and plastic screws. I selected to make use of the plastic ones as they’re lighter. Nonetheless they’re a bit bit too lengthy, you possibly can trim them to about 1.5mm thread size utilizing a nail clipper.

If the motor wires have slack, twist them barely earlier than set up to maintain them tidy and keep away from stress on the solder joints.

Putting in the Digital camera and Antenna

Set up the FPV digital camera and VTX antenna within the cover.

Plug the digital camera into the FC.

Putting in the Cover

I observed that the cover interfered with the UFL antenna connector, and this has been a identified challenge within the Air65 as some customers report that crashes could cause the connector to pop off.

To keep away from this, trim the cover barely to permit area for the connector. Contemplate including a dab of E6000 glue too to the UFL connector to assist safe it throughout crashes.

I made a mistake right here – the digital camera is the other way up LOL. Simply loosen the digital camera mount screw, and rotate the digital camera 180 levels.

Mounting the Propellers

Put the props on, relying on whether or not you need to run “props in” or “props out”. In my instance I’m working “props out”.

And that’s it—your Tiny Whoop meeting is full!

Decreasing Digital camera Title Angle

One challenge with the Air Cover is the excessive digital camera angle. To handle that, it’s possible you’ll copy my workaround. I used a 2mm zip tie.

Betaflight Configuration

As soon as your Tiny Whoop is assembled, it’s time to configure it in Betaflight. New to Betaflight? Try my newbie’s information: https://oscarliang.com/betaflight-firmware-setup/

Join the USB adapter to the flight controller (FC) and plug the USB cable into your pc.

Listed below are some recommendations on optimzing your tiny whoop configurations: https://oscarliang.com/best-tinywhoop-settings/

Under are screenshots of my Betaflight Configurator settings for this construct. When you’re utilizing the identical setup, you may simply replicate my configuration by copying and pasting my CLI file right here.

ESC Configuration

The BetaFPV AIO FC comes preloaded with Bluejay 0.19 firmware at 96KHz. I like to recommend flashing the newest model—Bluejay 0.21 at 48KHz—for optimized efficiency. You’ll be able to learn to flash Bluejay firmware right here: https://oscarliang.com/bluejay-blheli-s/

Flight Efficiency

I efficiently achieved my goal of a sub-17g construct, and the primary flight exceeded my expectations.

With a 1S 300mAh battery, I achieved a flight time of round 3:quarter-hour when flying aggressively—about 10-15 seconds lower than with the 27000KV motors. Nonetheless, the increase in flight efficiency is nicely value it, for my part. It’s much like shifting up from 23000KV to 27000KV; the construct felt considerably extra highly effective, agile, and nimble, virtually like flying a whoop with a lot much less weight.

Remaining Ideas

That is how one can construct a Tiny Whoop with distinctive flight efficiency for simply $130.

This construct presents one of many best methods to start out assembling FPV drones from scratch and acquire a stable understanding of them. It’s inexpensive, secure, and supplies a hands-on introduction to assembling, configuring, and flying an FPV drone. You’ll additionally develop primary soldering expertise with minimal threat, as solely the motors require soldering.

Whether or not you’re practising indoors or flying in tight areas, this Tinywhoop presents a enjoyable and academic expertise that may construct your confidence earlier than shifting on to bigger drones.