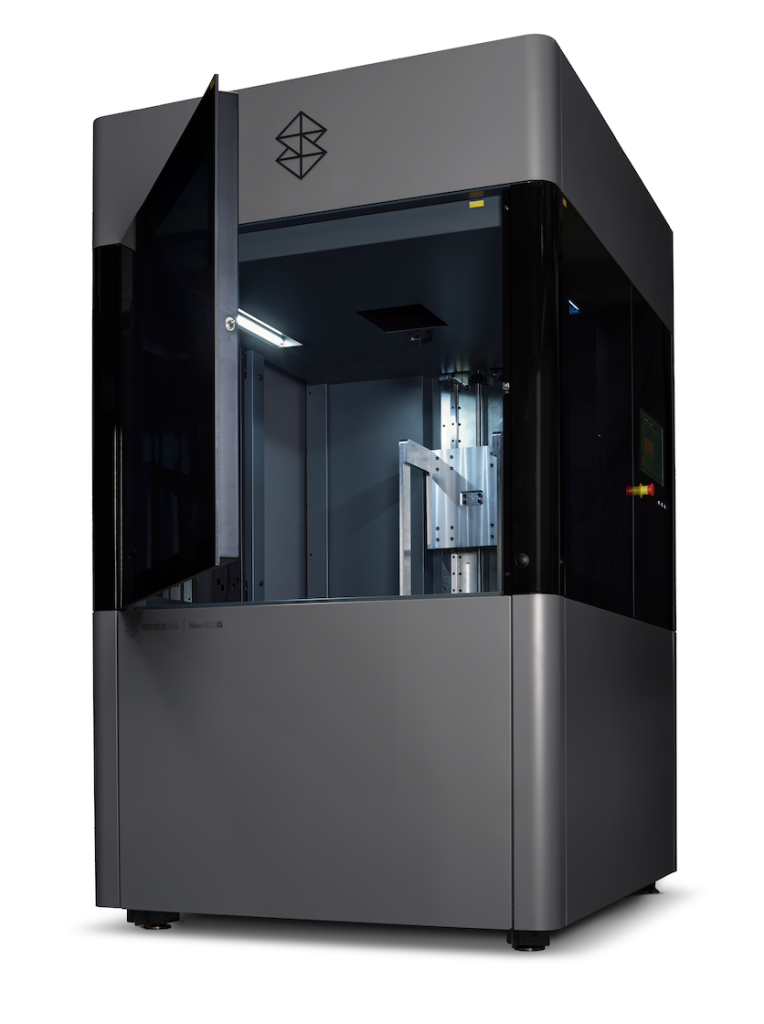

Stratasys Ltd (NASDAQ: SSYS), the worldwide supplier of polymer 3D printers, has launched the Neo®800+, a brand new stereolithography (SLA) 3D printer engineered for large-format, high-accuracy functions throughout automotive, aerospace, and industrial sectors. Introduced on the Additive Manufacturing Customers Group (AMUG) convention on March 31, 2025, and later showcased at Speedy + TCT 2025, the Neo800+ is the most recent addition to Stratasys’ rising SLA ecosystem.

The brand new system builds on the Neo800 platform, delivering as much as 50% sooner print speeds because of the combination of Stratasys’ proprietary ScanControl+™ know-how. Designed for demanding use circumstances like wind tunnel testing, tooling, and prototyping, the printer provides improved time-to-part, lowered post-processing, and enhanced reliability.

“Engineered with precision and efficiency in thoughts, the Neo800+ is designed to satisfy the rising calls for of industries like automotive and aerospace,” mentioned Wealthy Garrity, Chief Enterprise Unit Officer at Stratasys. “Whether or not you’re designing prototypes or manufacturing end-use components, the Neo800+ delivers distinctive throughput and reliability.”

Efficiency and reliability upgrades

Along with sooner print speeds, the Neo800+ options a number of enhancements aimed toward bettering uptime and print success. These embrace Vacuum System Safety, Z-Stage Collision Detection, and real-time environmental monitoring. Collectively, these upgrades contribute to increased half yield, lowered machine downtime, and a decrease price per half.

The upgraded laser and optics system is optimized for high-energy supplies, enabling the printer to ship distinctive accuracy throughout a variety of geometries. This additionally reduces the necessity for post-processing, making the printer more cost effective for high-throughput workflows.

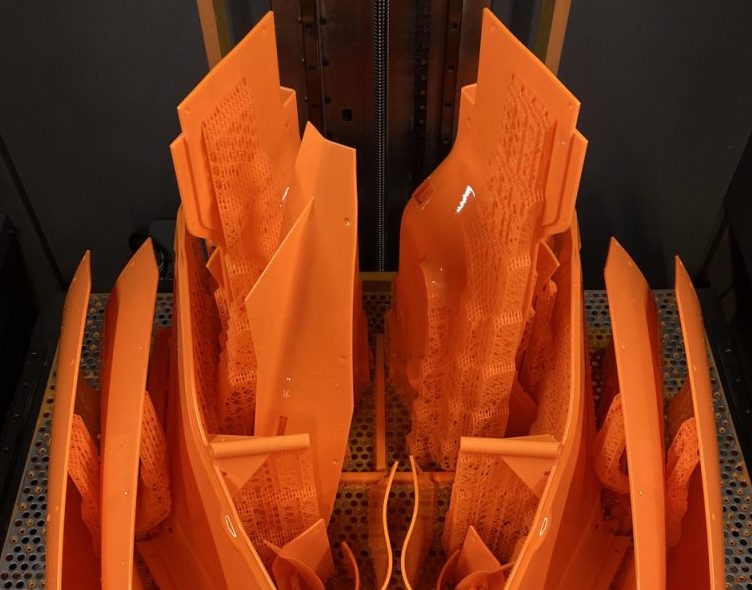

Stratasys Direct Manufacturing, one of many early adopters of the Neo800+, reported vital enhancements in turnaround time and half high quality. “The improved pace has allowed us to extend throughput and keep open capability in addition to supply faster turnaround occasions to our prospects,” mentioned Sean Schoonmaker, Director of Operations. “The standard and consistency of the prints have been excellent, with a superb floor end that helps save on post-processing time for beauty fashions.”

Supplies and ecosystem

The Neo800+ is optimized to be used with ScanControl+ Prepared Supplies from Somos®, together with the newly launched WaterShed® XC+. This resin relies on the broadly used WaterShed XC 11122, providing related optical readability and easy floor end, whereas enabling a lot sooner scan speeds. This makes it significantly well-suited for complicated clear components in automotive lighting, fluid stream testing, and client electronics.

Stratasys helps the Neo800+ with a full SLA workflow ecosystem that features the cloud-connected GrabCAD Print Construct Preparation Software program and post-processing options designed to streamline operations. These instruments purpose to simplify setup, scale back operator intervention, and guarantee repeatability at scale.

Stratasys’ enlargement into high-throughput SLA with the Neo800+ alerts a continued dedication to assembly industrial calls for throughout prototyping and low-volume manufacturing. The corporate’s broader technique consists of multi-technology choices throughout FDM, SAF, P3, and now high-speed SLA, every tailor-made for particular business wants.

Evolution of business SLA 3D printing

Throughout the 3D printing business, SLA know-how is being reimagined by improvements in {hardware} and supplies. At TCT Asia 2025, UnionTech showcased industrial SLA platforms with enhanced optics and throughput, reinforcing the relevance of SLA in tooling and end-use manufacturing. Among the many varied functions showcased, tire mildew printing stood out as probably the most precision-intensive.

Atum3D, in the meantime, is pushing boundaries with hybrid DLP-SLA know-how licensed from the College of Amsterdam, making a hybrid SLA course of that mixes photograph and stereolithography to allow the manufacturing of components with high-resolution options at scale.

Sprybuild has launched a novel conveyor belt SLA system aimed toward enabling steady, automated half manufacturing, which highlights the opportunity of high-volume manufacturing throughout varied sectors similar to automotive, client items, aerospace, and healthcare.

On the supplies entrance, researchers from Carleton College and the College of Northern British Columbia are actually integrating quantum dots into SLA resins, considerably bettering half power and thermal resistance. These developments spotlight a rising business consensus: SLA is now not restricted to easy floor prototypes, it’s turning into a critical device for industrial manufacturing.

Who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You too can observe us on LinkedIn and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits NEO800 3D printing techniques. Picture through Stratasys.