An experimental new undersea robotic reveals nice promise to be used within the repairs of offshore renewable power platforms. As a result of it has the flexibility to climb vertical underwater surfaces – and paint them – it is often called the Crawfish.

Whether or not they’re harnessing the ability of the wind, tidal currents or waves, offshore power constructions require common inspection, upkeep, and repairs. Divers are sometimes recruited to carry out the underwater facets of those jobs, though utilizing such personnel may be pricey and time-consuming … to not point out dangerous to the divers themselves.

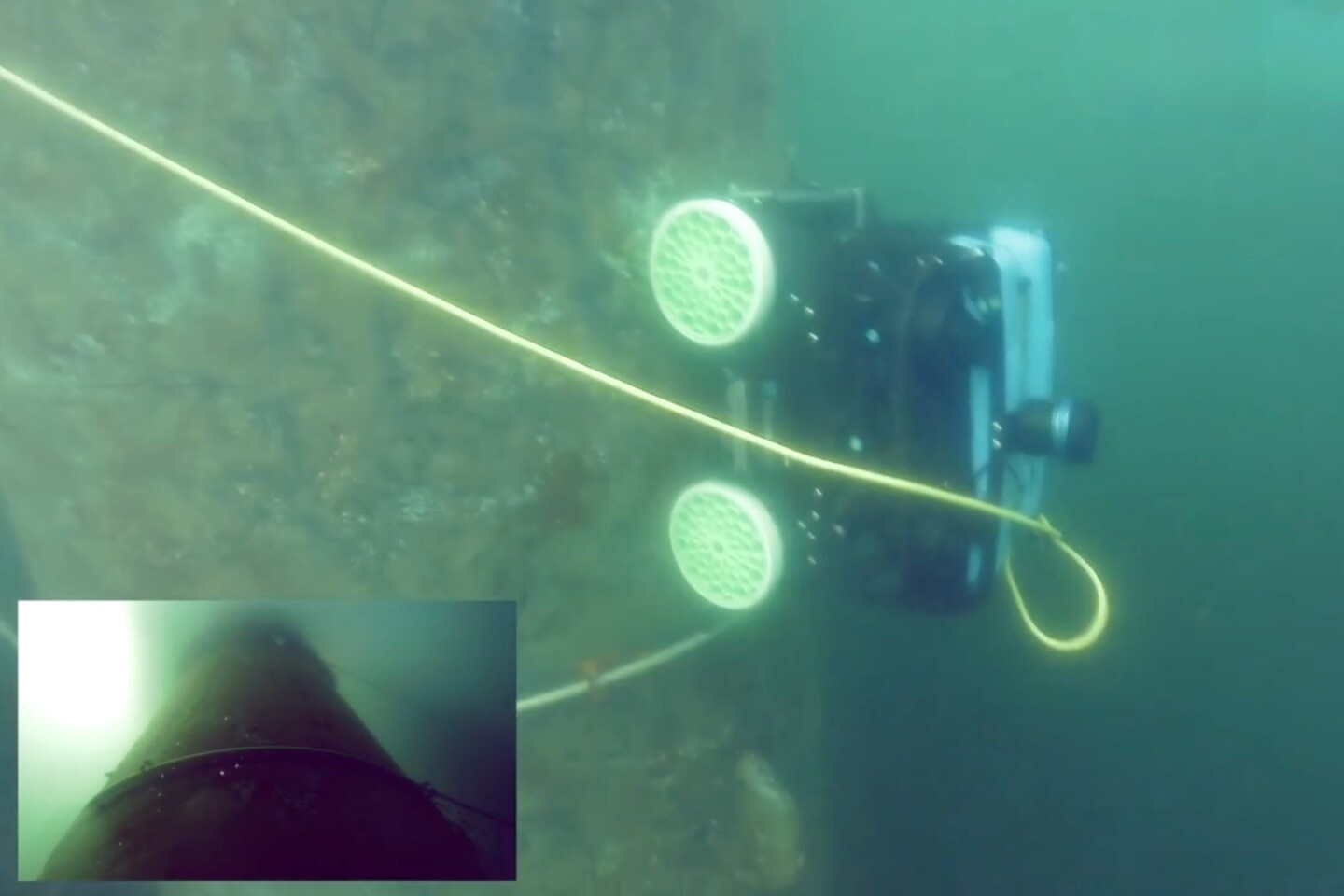

That is the place the Crawfish is available in. Developed by scientists at Germany’s Fraunhofer Good Ocean Applied sciences analysis group, the tethered machine is definitely made up of two linked parts.

On high is a commercially out there BlueROV2 remotely operated car made by California-based firm Blue Robotics. On the underside is a crawler unit which options 4 direct-drive elastomer wheels together with quite a lot of instruments resembling a digicam, brush, and particular sensor-reading head.

Fraunhofer

As a result of the robotic weighs simply 22 kg (48.5 lb), it may be lowered into the water by two or three human employees – no crane is required. As soon as the machine is underwater, a topside operator remotely steers it over to the construction using the BlueROV2’s digicam and thrusters.

Upon reaching the vertical floor of the platform, the BlueROV’s thrusters apply as much as 90 Newtons (20 lb-force/9 kg-force) of “downward” power (or horizontal power, relying on the way you have a look at it), retaining the Crawfish held firmly in place. The robotic then makes its method alongside the floor utilizing its powered wheels.

Because the bot does so, its digicam is used to remotely verify for harm to the construction’s anti-corrosion paint, whereas its reader head is used to wirelessly acquire information from CoMoBelt sensor collars positioned at varied factors on the platform. These collars, that are made by Fraunhofer, detect cracks in seam welds through built-in ultrasonic transceivers.

If harm to the paint is detected, it may be patched utilizing a two-part coating materials which is injected into the robotic’s remotely operated brush. Defective welds might conceivably even be mounted utilizing an onboard welding head.

In its present type, the Crawfish can descend to a most depth of fifty m (164 ft) and is ready to crawl (utilizing 50 Newtons of downforce) for 25 minutes per battery-charge. You’ll be able to see it in free-swimming and structure-crawling motion, within the video beneath.

Fraunhofer Crawfish offshore power platform robotic

Supply: Fraunhofer