Researchers from Stanford College have developed a novel high-speed 3D printing course of that may produce as much as a million, extremely complicated microscale particles per day.

Whereas the 3D printing of microscopic fashions is a rising space inside numerous industries, corresponding to drug supply, microelectronics, and microfluidics, a variety of challenges have restricted the size of manufacturing. The necessity to exactly management the supply of sunshine, stage motion and resin properties usually ends in trade-offs between velocity, geometric management, uniformity, and materials properties.

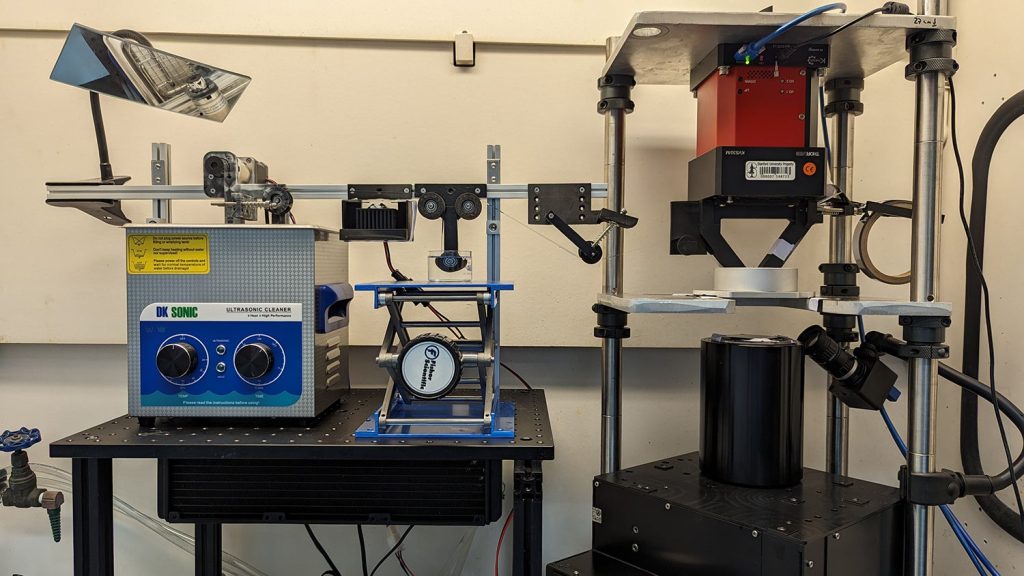

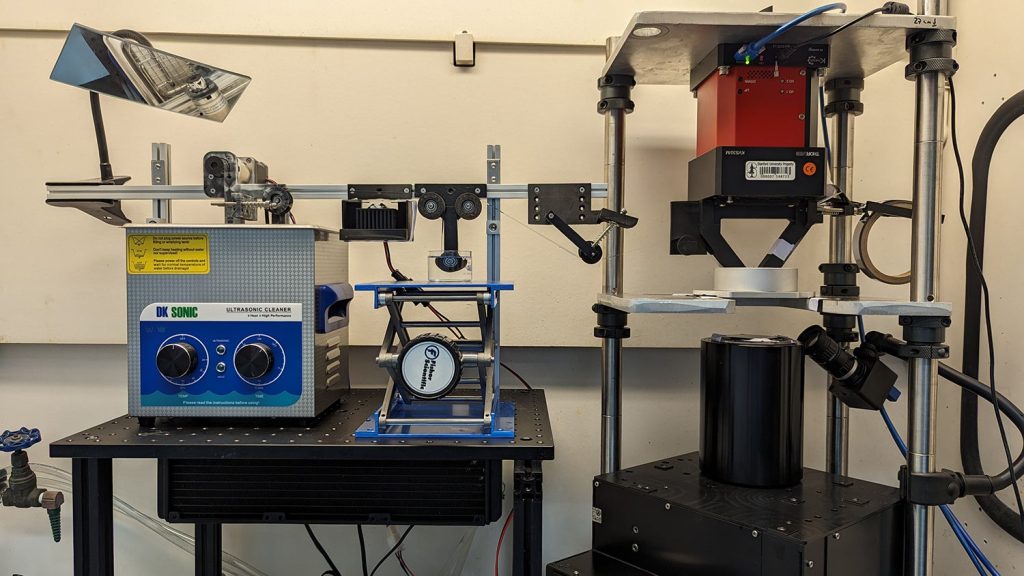

To beat these challenges, the Stanford crew leveraged a resin-based 3D printing approach known as steady liquid interface manufacturing, or CLIP. The researchers built-in this course of right into a production-line setup to create a brand new approach, dubbed roll-to-roll CLIP (r2rCLIP).

This enabled batches of micro-scale fashions to be 3D printed, washed, cured and eliminated mechanically with out the necessity for guide enter, significantly growing manufacturing speeds. This strategy is claimed to allow high-volume 3D printing of intricate microscopic designs, providing notable potential for biomedical, analytical and superior supplies functions.

“We will now create far more complicated shapes all the way down to the microscopic scale, at speeds that haven’t been proven for particle fabrication beforehand, and out of a variety of supplies,” defined Jason Kronenfeld, a PhD candidate within the DeSimone lab at Stanford College.

The findings, titled ‘Roll-to-roll, high-resolution 3D printing of shape-specific particles,’ have been revealed within the tutorial journal Nature.

Scaling micro-3D printing to mass manufacturing

CLIP 3D printing was co-developed by Joseph DeSimone, Sanjiv Sam Gambhir Professor in Translational Drugs at Stanford Drugs, who patented the expertise via his agency Carbon in 2015.

The photopolymerization course of employs UV mild to shortly remedy resin right into a desired form. Slightly than curing the resin layer by layer, as with DLP and SLA expertise, CLIP employs a steady 3D printing course of that considerably reduces fabrication time.

The important thing to this system is an oxygen-permeable window, which creates a skinny polymerization-free space within the resin on the backside of the vat. This ‘lifeless zone’ prevents liquid resin from curing and sticking to the projection window, permitting for quicker 3D printing speeds and the manufacturing of extra fragile inexperienced elements.

To develop their new high-volume micro-3D printing course of, the Stanford crew changed a CLIP 3D printer’s static construct plate with a steady and modular ‘roll-to-roll’ movie different.

The aluminum-coated polyethylene terephthalate (PET) movie is first tensioned and fed via the CLIP 3D printer. Right here, a whole bunch of microscopic shapes are concurrently fabricated onto the movie. The PET movie meeting line then strikes the 3D printed shapes to totally different stations which mechanically wash, remedy, and take away them. Lastly, the empty movie could be rolled again up.

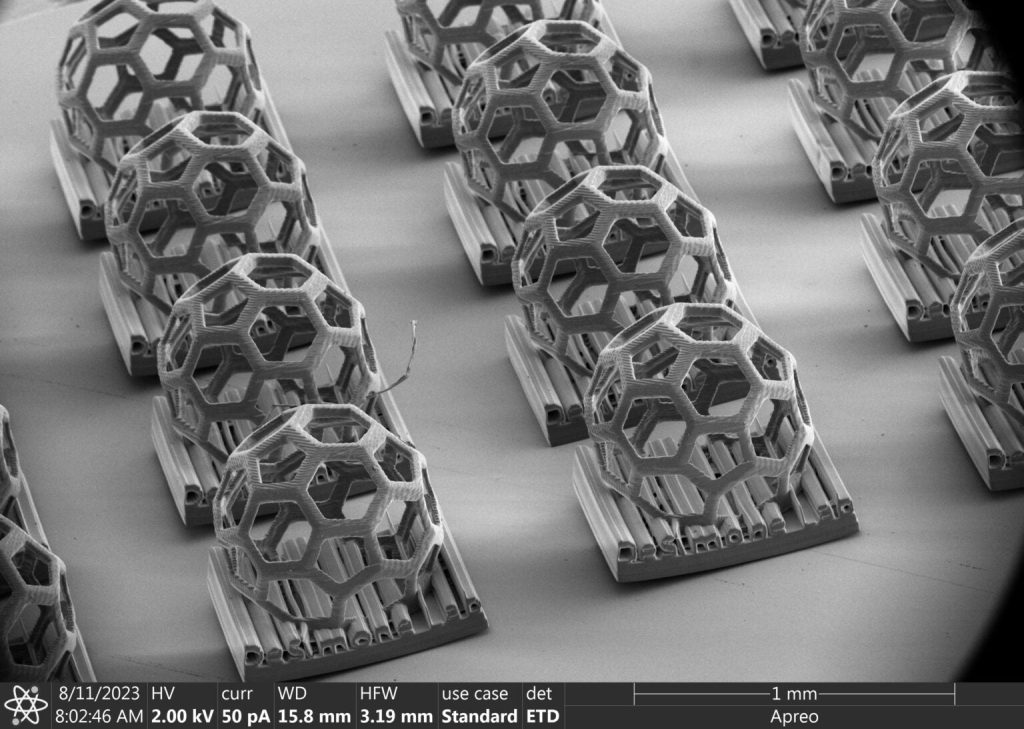

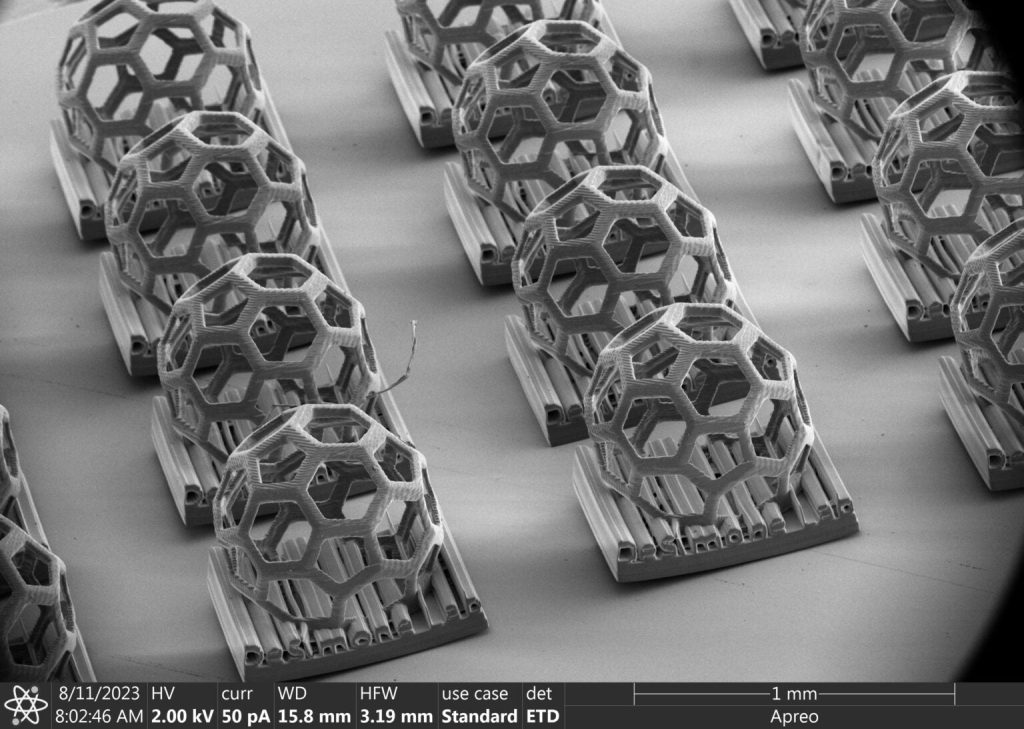

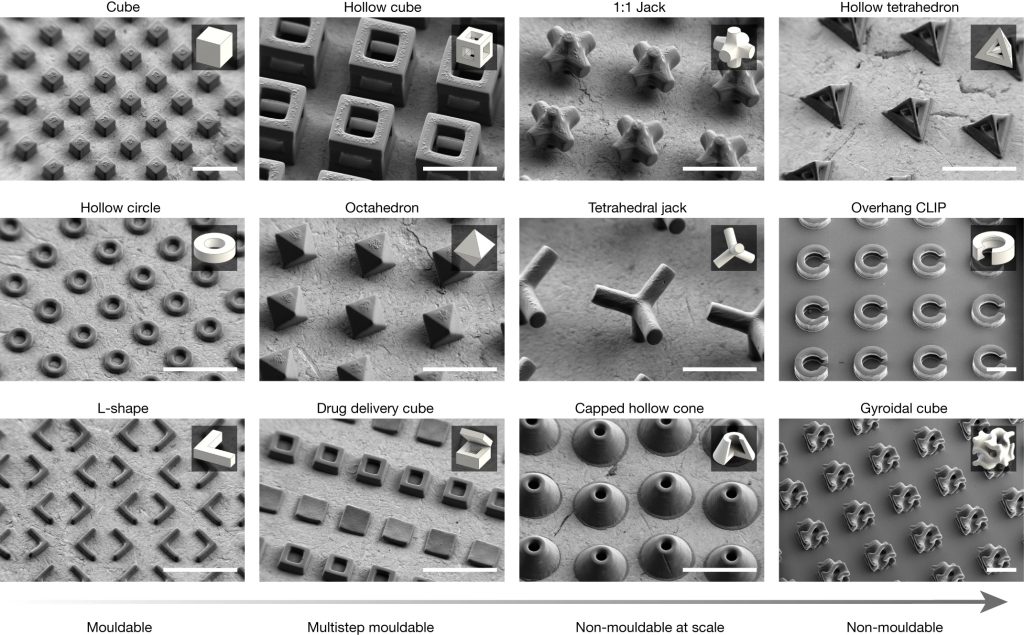

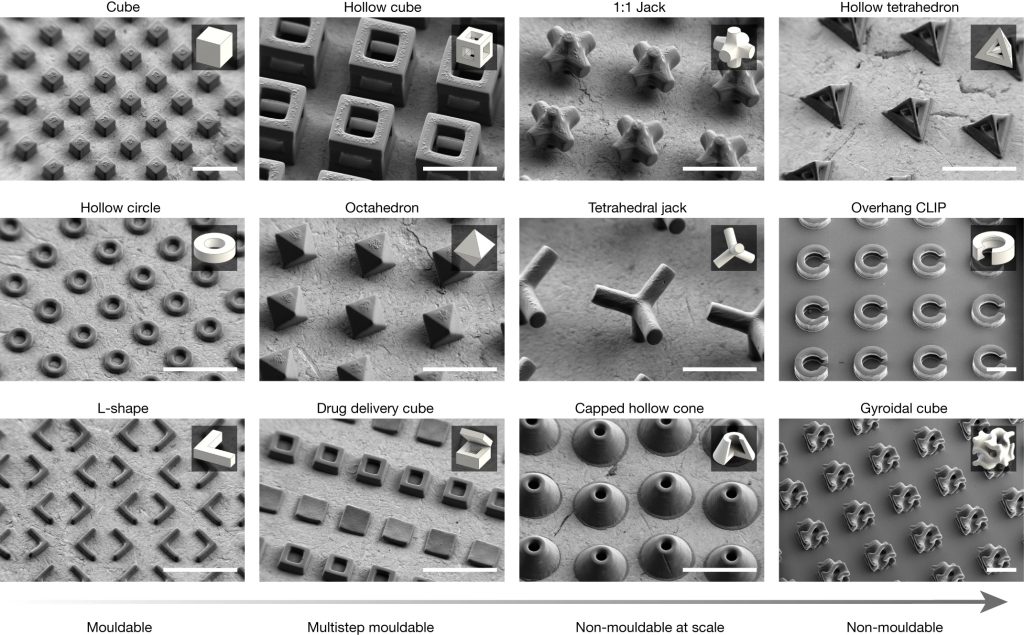

The 3D printer is able to fabricating particles as much as 200 µm in measurement and at characteristic resolutions of two.0µm. To show the power of r2rCLIP to 3D print dimensionally complicated constructions, the researchers produced a spread of shapes with growing ranges of geometric complexity. One such design was a three-dimensional illustration of the DeSimone lab emblem, which featured a micron-scale buckyball geometry.

In typical micro-3D printing, batches of particles should be manually processed, which could be sluggish and laborious. Nevertheless, as a totally automated course of, r2rCLIP can efficiently 3D print as much as a million particles in a single day.

Because of this excessive throughput, it’s believed that r2rCLIP might be used for the mass manufacturing of parts starting from microrobots and cargo supply techniques, to drug supply vessels. Certainly, the Stanford crew has already experimented with 3D printing each arduous and tender particles manufactured from ceramics and hydrogels.

“Our strategy is distinctively able to producing high-resolution outputs whereas preserving the fabrication tempo required to satisfy the particle manufacturing volumes that specialists contemplate important for numerous functions,” said Kronenfeld.

Seeking to the longer term, the Stanford researchers hope that r2rCLIP 3D printing shall be extra extensively adopted by different researchers, industries, and high-value mass-production functions.

Scaling resin 3D printing to mass manufacturing

Whereas this analysis seeks to scale the manufacturing of microscale particles, the potential of resin 3D printing for the mass manufacturing of larger-scale elements together with machine elements, fixtures, dentures, and listening to aids can be being explored.

Again in 2019, scientists on the College of Michigan developed a high-speed resin 3D printing course of 100 instances quicker than commercially accessible applied sciences. Stated to rival the CLIP strategy, the strategy employs a twin mild supply of UV and blue mild.

By utilizing a resin combination that accommodates each picture initiators and inhibitors, the lights could be tuned to begin and cease the curing course of as required. This strategy can obtain an analogous ‘lifeless zone’ impact as with CLIP, however with out the necessity for a bodily window.

The College of Michigan crew efficiently used this strategy to realize 3D print speeds of roughly 2 m/hour. In consequence, the researchers said that this methodology might provide worth for firms trying to make use of additive manufacturing in mass manufacturing.

Elsewhere, Israeli start-up Sprybuild not too long ago unveiled its new Stereolithography (SLA) 3D printer that includes a steady construct course of on a conveyor belt, which might provide potential in mass manufacturing functions. Using a magnetic mechanism, the conveyor belt achieves floor stability whereas enabling the automated launch of 3D printed elements, lowering downtime and boosting productiveness.

Throughout testing, the system efficiently 3D printed dental fashions at a velocity of 55 mm/min. Nevertheless, Sprybuild claims that the 3D printer can attain speeds of as much as 150 mm/min, 2.5 instances quicker than the common industrial resin 3D printer.

One firm that has already leveraged resin-based additive manufacturing to realize mass manufacturing is Utah-based 3D printed elements producer Merit3D. Final yr, the agency utilized 20 Photocentric Liquid Crystal Magna LCD resin 3D printers to ship an order for a million 3D printed elements.

Billed as ‘the biggest ever 3D printed elements order,’ the 3D printers had been leveraged to provide hangers for epoxy merchandise for Florida-based adhesives producer Adhesive Know-how Company at a fee of 40,000 items per week.

The deal shaped a part of Merit3D’s ongoing mission to reshore the mass manufacturing of elements into the US. This mission is being supported by the $10 million Utah Manufacturing Modernization Grant, which seeks to Utah companies to develop manufacturing inside the state.

What does the way forward for 3D printing maintain?

What near-term 3D printing traits have been highlighted by business specialists?

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture exhibits the 3D-printed DeSimone lab emblem, that includes a buckyball geometry. Picture through DeSimone Analysis Group, SEM courtesy of Stanford Nano Shared Amenities.