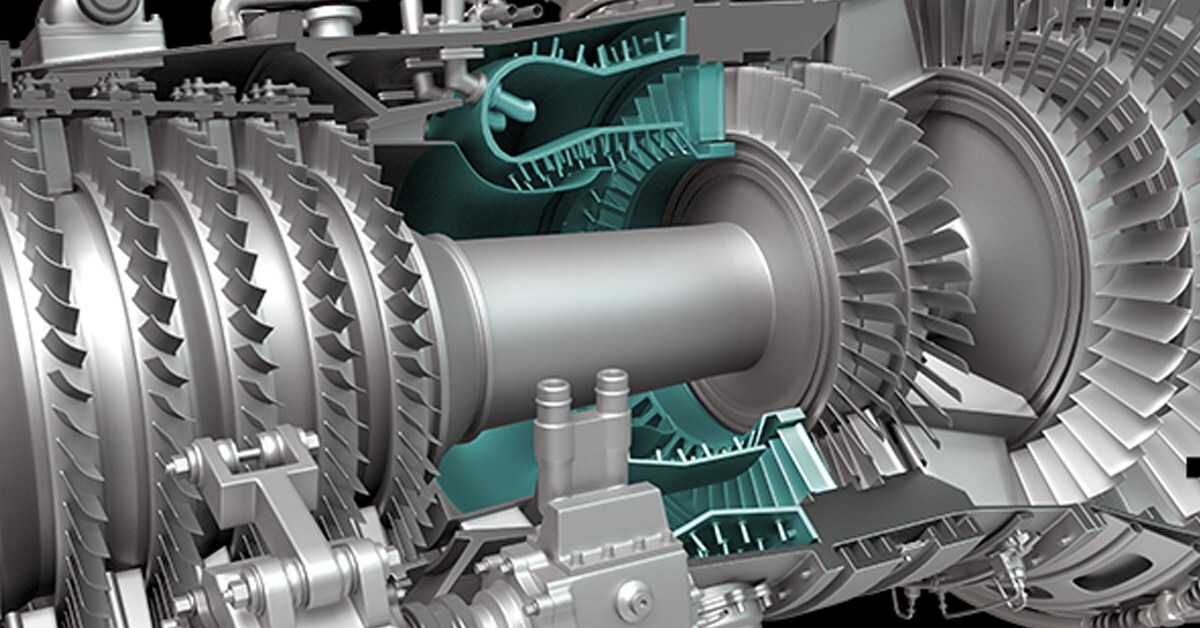

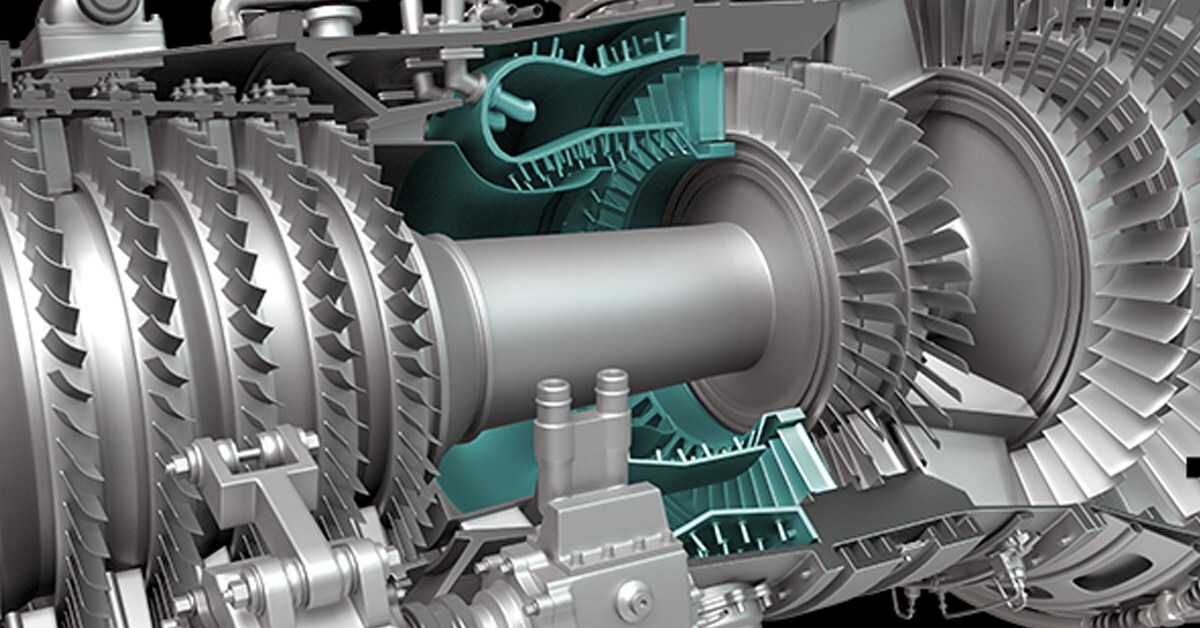

QuesTek Improvements has partnered with a world niobium producer to develop a high-temperature alloy designed for additive manufacturing. The undertaking targets aerospace and vitality business purposes, with enter from GE Vernova and Technetics Group to align the fabric with manufacturing necessities throughout propulsion, energy technology, and superior gear sectors.

The collaboration goals to handle provide chain disruptions and supplies shortage affecting superior manufacturing industries. The brand new printable alloy is meant to cut back reliance on conventional manufacturing processes whereas enabling sooner manufacturing of high-performance components for high-temperature purposes.

QuesTek says the alloy design will remove lengthy tooling lead instances and forge limitations that at the moment gradual improvement in high-temperature makes use of. The fabric is being developed to offer manufacturing flexibility as firms navigate provide chain challenges and shifting market situations.

The undertaking contains sustainability issues, with the alloy designed to assist extra environment friendly engines and cut back manufacturing waste. This method aligns with business targets for decrease emissions and improved system effectivity in vitality purposes.

The multi-phase improvement course of makes use of QuesTek’s ICMD design platform to maneuver from digital simulation to bodily validation. QuesTek focuses on computational supplies engineering and claims its Supplies by Design know-how reduces improvement time and prices whereas growing materials efficiency in comparison with conventional strategies.