| Feb 02, 2024 |

(Nanowerk Information) Oxidation can degrade the properties and performance of metals. Nevertheless, a analysis group co-led by scientists from Metropolis College of Hong Kong (CityU) lately discovered that severely oxidized metallic glass nanotubes can attain an ultrahigh recoverable elastic pressure, outperforming most standard super-elastic metals. |

|

In addition they found the bodily mechanisms underpinning this super-elasticity. Their discovery implies that oxidation in low-dimension metallic glass may end up in distinctive properties for functions in sensors, medical gadgets and different nanodevices. |

|

The findings have been revealed in Nature Supplies (“Oxidation-induced superelasticity in metallic glass nanotubes”). |

|

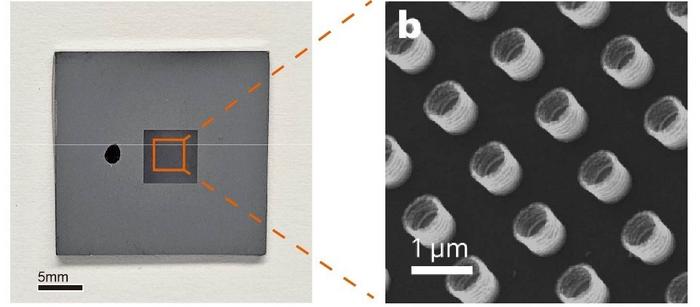

| (Left) Picture of metallic-glass nanotubes fabricated on silicon and (proper) a scanning electron microscopy picture of the metallic-glass nanotubes. (Picture: Professor Yang Yong’s analysis group / Metropolis College of Hong Kong) |

|

Lately, the purposeful and mechanical properties of low-dimensional metals, together with nanoparticles, nanotubes and nanosheets, have garnered consideration for his or her potential functions in small-scale gadgets, reminiscent of sensors, nano-robots and metamaterials. Nevertheless, most metals are electrochemically energetic and prone to oxidation in ambient environments, which regularly degrades their properties and functionalities. |

|

“Metallic nanomaterials have a excessive surface-to-volume ratio, which could be as much as 108m-1. So in precept, they’re anticipated to be significantly vulnerable to oxidation,” stated Professor Yang Yong, within the Division of Mechanical Engineering at CityU, who led the analysis group collectively along with his collaborators. “To make use of low-dimensional metals to develop next-generation gadgets and metamaterial, we should totally perceive the hostile results of oxidation on the properties of those nanometals after which discover a solution to overcome them.” |

|

Subsequently, Professor Yang and his group investigated oxidation in nanometals, and in sharp distinction to their expectation, they discovered that severely oxidized metallic glass nanotubes and nanosheets can attain an ultrahigh recoverable elastic pressure of as much as about 14% at room temperature, which outperforms bulk metallic glasses, metallic glass nanowires, and lots of different super-elastic metals. |

|

They made metallic glass nanotubes with a median wall thickness of simply 20nm, and fabricated nanosheets from completely different substrates, reminiscent of sodium chloride, polyvinyl alcohol and traditional photoresist substrates, with completely different ranges of oxygen focus. |

|

They then carried out 3D atom probe tomography (APT) and electron power loss spectroscopy measurements. In each the outcomes, oxides have been dispersed inside the metallic glass nanotubes and nanosheets, in contrast to standard bulk metals, during which a strong oxide layer varieties on the floor. Because the oxygen focus within the samples elevated owing to metallic–substrate reactions, related and percolating oxide networks have been fashioned contained in the nanotubes and nanosheets. |

|

In-situ microcompression measurements additionally revealed that the severely oxidized metallic glass nanotubes and nanosheets exhibited a recoverable pressure of 10–20%, which was a number of occasions greater than that of most standard superelastic metals, reminiscent of form reminiscence alloys and gum metals. The nanotubes additionally had an ultra-low elastic modulus of about 20–30 GPa. |

|

To know the mechanism behind this, the group carried out atomistic simulations, which indicated that the superelasticity originates from extreme oxidation within the nanotubes and could be attributed to the formation of a damage-tolerant percolation community of nano-oxides within the amorphous construction. These oxide networks not solely limit atomic-scale plastic occasions throughout loading, but additionally result in the restoration of elastic rigidity on unloading in metallic glass nanotubes. |

|

“Our analysis introduces a nano-oxide engineering strategy for low-dimensional metallic glasses. The morphology of nano-oxides inside metallic-glass nanotubes and nanosheets could be manipulated by adjusting the oxide focus, starting from remoted dispersions to a related community,” stated Professor Yang. |

|

“With this strategy, we are able to develop a category of heterogeneous nanostructured ceramic-metal composites by mixing metals with oxides on the nanoscale. Such composites have nice potential for numerous future business functions and nanodevices working in harsh environments, reminiscent of sensors, medical gadgets, micro- and nano-robots, springs and actuators,” he added. |