Northwestern College’s Supplies Science and Engineering division has carried out a brand new hands-on method to instructing smooth supplies ideas. Professor Ryan Truby’s MAT_SCI 331: Mushy Supplies course now options 3D Printing Resin Design Labs, the place college students create and optimize their very own printing supplies. Pupil groups work with a dozen desktop resin 3D printers to develop customized formulations for particular functions.

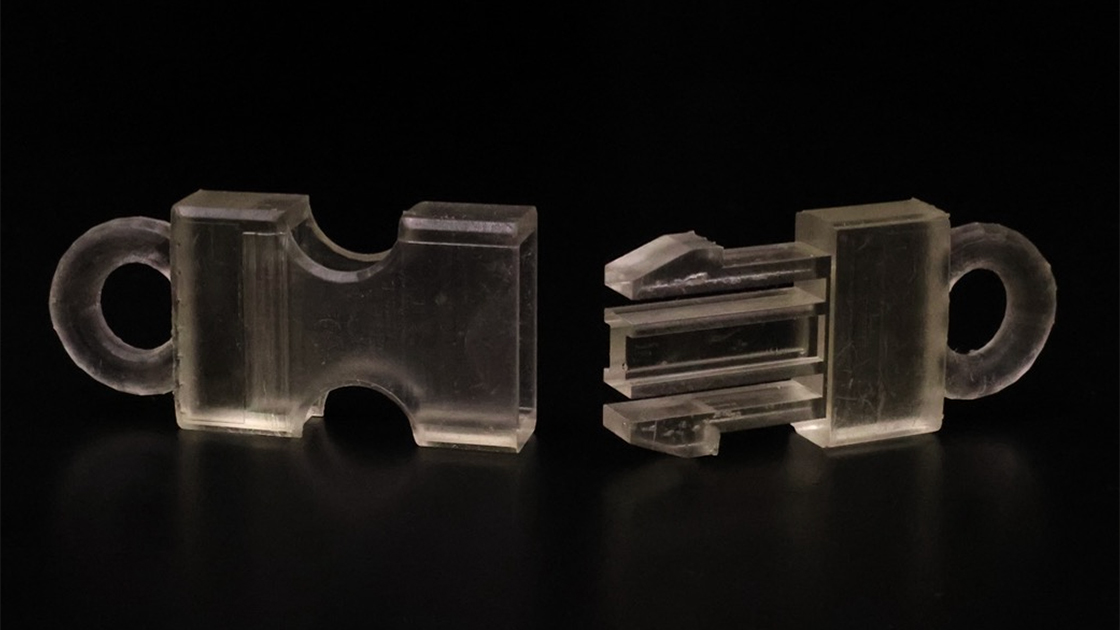

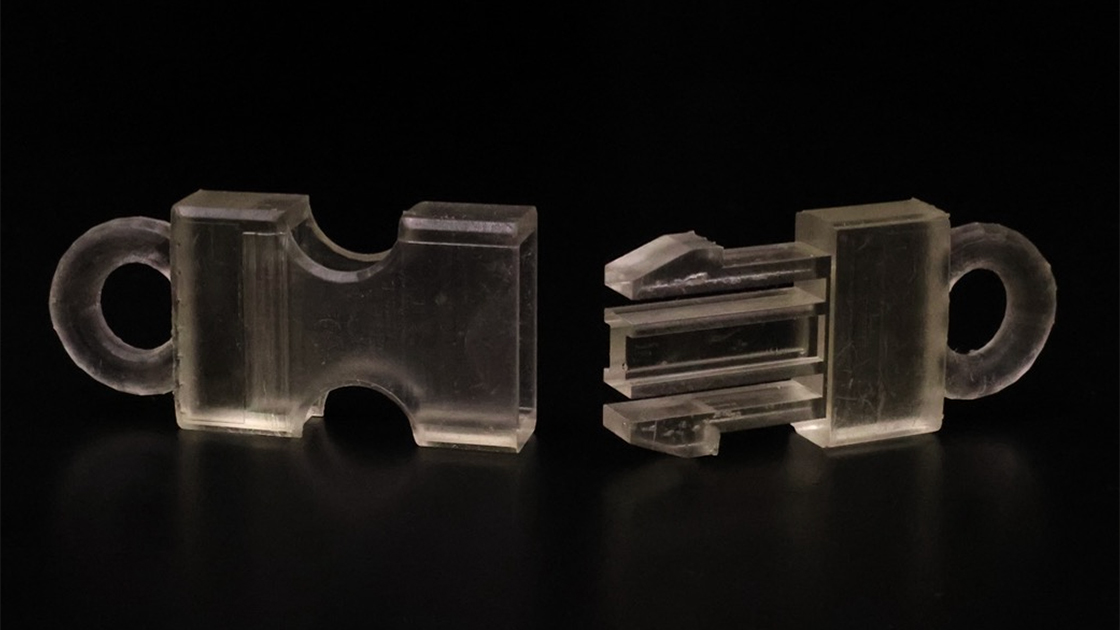

The redesigned course challenges college students to provide purposeful plastic buckles able to withstanding heavy hundreds. Members progress by way of six intensive labs specializing in 3D printing, supplies characterization, and mechanical testing. This method integrates theoretical ideas with sensible software, permitting college students to expertise firsthand how modifying resin formulations impacts printed half efficiency.

“3D printing as a expertise requires interdisciplinary supplies science and engineering data, spanning natural chemistry and polymer physics to rheology and mechanics,” mentioned Truby, who holds positions as June and Donald Brewer Junior Professor and assistant professor of supplies science and engineering and of mechanical engineering. The initiative acquired help by way of Truby’s 2023-24 Searle Fellowship and a 2023 Murphy Society Award shared with Professor Jonathan Emery.

College students report optimistic experiences with the hands-on format. “The category significantly surpassed my expectations, providing much more hands-on expertise than anticipated,” mentioned third-year undergraduate Julia Wiater. Fellow scholar Hayden Williams added, “I felt I had a considerable amount of management, which was good as most different lab-based programs concentrate on one very particular take a look at or experiment.”

Supply: mccormick.northwestern.edu