Farsoon Applied sciences, a China-based producer of industrial-grade 3D printing techniques, has launched the FS191M, a next-generation steel powder mattress fusion (PBF) machine designed to boost productiveness and cost-efficiency throughout a spread of commercial makes use of. Constructing upon the inspiration of its FS121M system launched in 2016, the brand new system goals to supply a scalable resolution for each pilot initiatives and low-volume manufacturing.

“The FS191M builds on the success of our small-volume FS121M system,” mentioned Wenyu Guo, Director of Farsoon’s Metallic Product Line. “Over the previous six years, we’ve collaborated carefully with industrial and analysis companions to optimize productiveness, streamline workflows, and develop course of capabilities—all whereas sustaining a low value of possession. This strategy is enabling us to unlock new markets, together with client merchandise, tooling, and extra.”

With an ordinary construct cylinder measuring 191 mm in diameter and 199 mm in peak, the FS191M offers a construct quantity of 5.64 liters—almost 4 occasions that of its predecessor. Geared up with a 500-watt fiber laser, the system is designed for small-batch manufacturing requiring excessive element and precision. An optionally available smaller construct platform measuring 78 mm by 80 mm is obtainable for analysis and improvement functions, lowering materials prices and enhancing flexibility. The power to change between platform sizes permits customers to transition seamlessly from validation to manufacturing.

Incorporating cutting-edge options aimed toward enhancing print high quality and operational effectivity, the FS191M features a high-precision F-Theta lens for constant laser efficiency, an built-in filtration system for optimum working circumstances, and in-chamber monitoring cameras that present real-time oversight of the printing course of. The machine additionally options an modern recoater design for uniform powder distribution and a complicated management card for enhanced course of management. Its open parameter technique allows customers to completely customise materials processing parameters, making it adaptable to quite a lot of industrial purposes.

For research-focused initiatives, the FS191M affords further capabilities equivalent to a Help Discount System (SRS), which minimizes the necessity for help constructions, thereby lowering materials utilization and post-processing efforts. The system additionally contains high-resolution soften pool monitoring for real-time high quality assurance and an modern 3D structured mild monitoring system. This expertise makes use of structured laser detection for high-precision Z-axis monitoring, lowering powder recoating defects like warping and scratches. Superior optical options like laser beam shaping are built-in to boost effectivity and half high quality.

Farsoon is now accepting purposes for its early adopter program for the FS191M. The corporate is showcasing the system at Formnext 2024 in Frankfurt, sales space 11.0-E11.

Developments in Metallic PBF Know-how

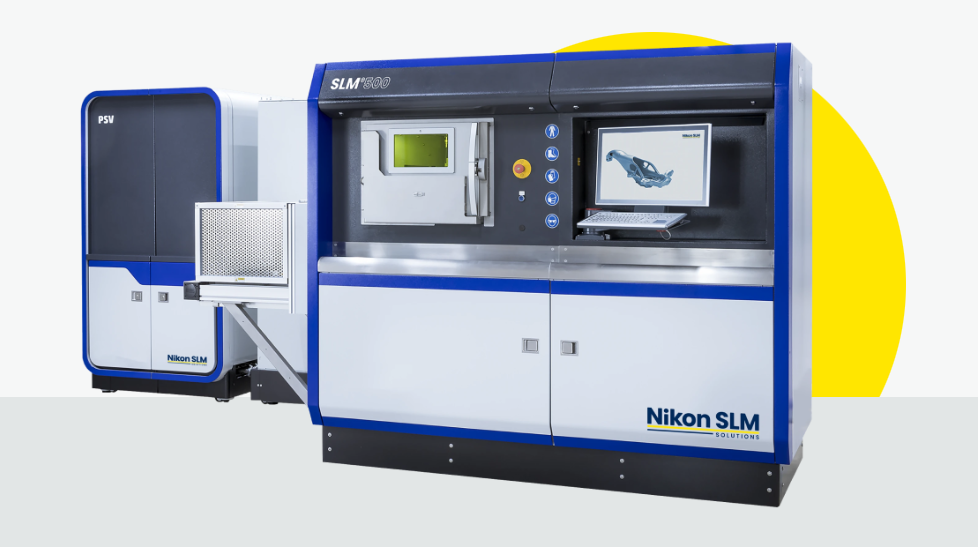

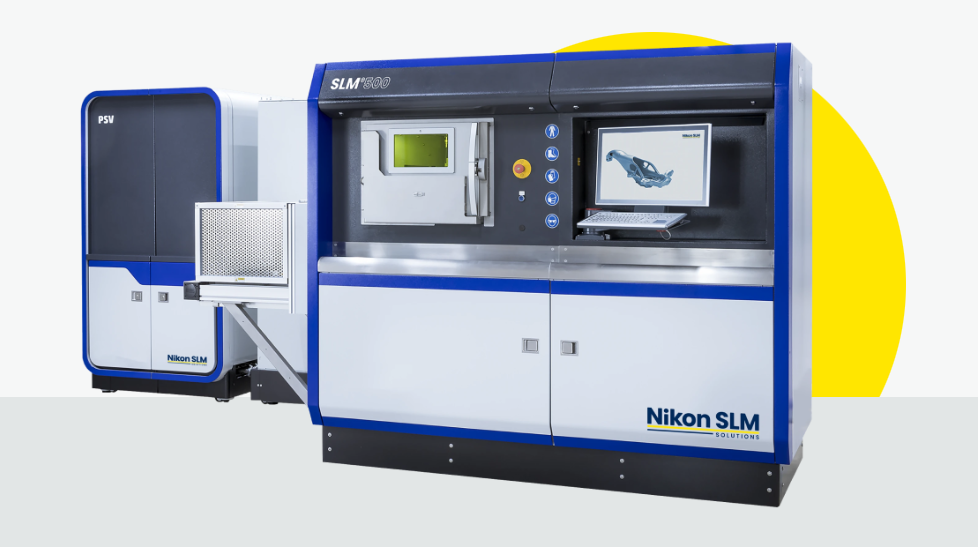

Nikon SLM Options, a world chief in steel 3D printing expertise, not too long ago unveiled redesigned variations of their PBF techniques: SLM 280, SLM 280 Manufacturing Sequence, and SLM 500 machines. These fashions function superior recoater brushes, everlasting filter modules, and highly effective 700W lasers aimed toward rising productiveness and reliability. With a assured minimal uptime of 85%—and exceeding 90% in present installations—these techniques replicate ongoing progress in steel additive manufacturing.

Equally, Eplus3D, a developer of steel additive manufacturing techniques, launched the EP-M4750, a steel 3D printer designed for large-scale batch manufacturing in industries like aerospace and automotive. That includes a construct chamber of 450 x 750 x 530 mm and geared up with as much as 4 500 W fiber lasers, the EP-M4750 achieves print speeds of as much as 70 cm³/h. The machine helps quite a lot of metals and contains options like an optimized gasoline circulation system and adjustable layer thickness, enhancing each effectivity and half high quality.

Your voice issues within the 2024 3D Printing Trade Awards. Vote Now!

What is going to the way forward for 3D printing seem like?

Which latest developments are driving the 3D printing business, as highlighted by consultants?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.Keep related with the newest in 3D printing by following us on Twitter and Fb, and don’t overlook to subscribe to the 3D Printing Trade YouTube channel for extra unique content material.

Featured picture exhibits the newly unveiled Farsoon FS191M. Photograph by way of Farsoon Applied sciences.