Avio Aero, a outstanding participant within the aerospace trade, is increasing its additive manufacturing capabilities with a brand new facility in Brindisi, Italy. Scheduled for completion by the top of 2018, this 1,000 sq. meter facility will home state-of-the-art tools for steel 3D printing.

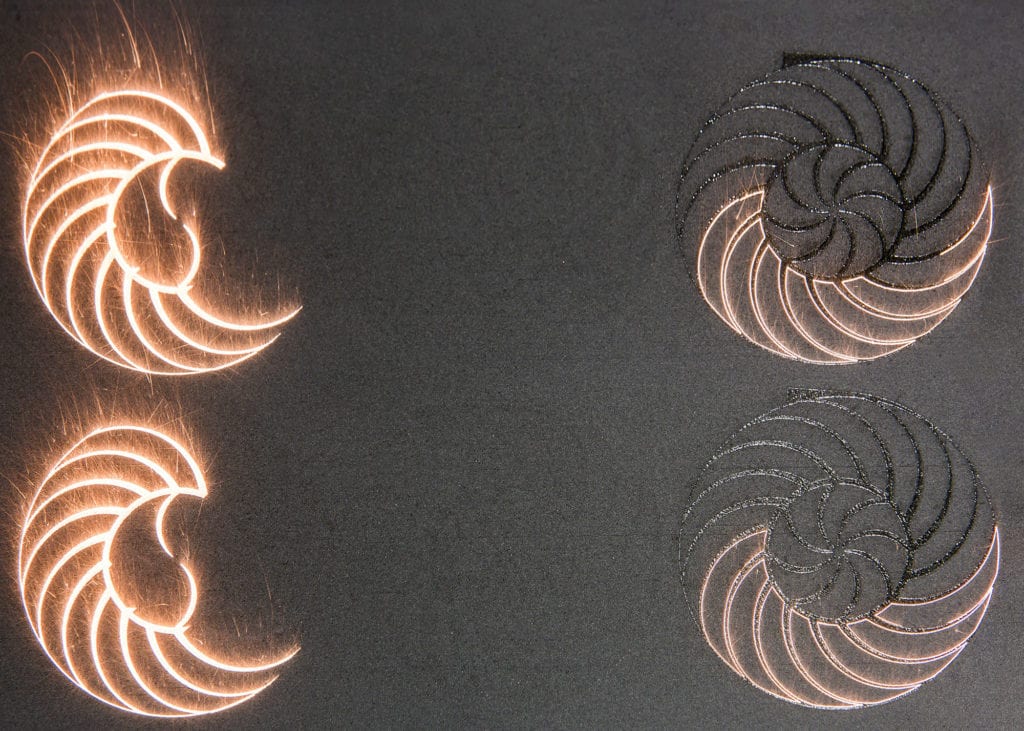

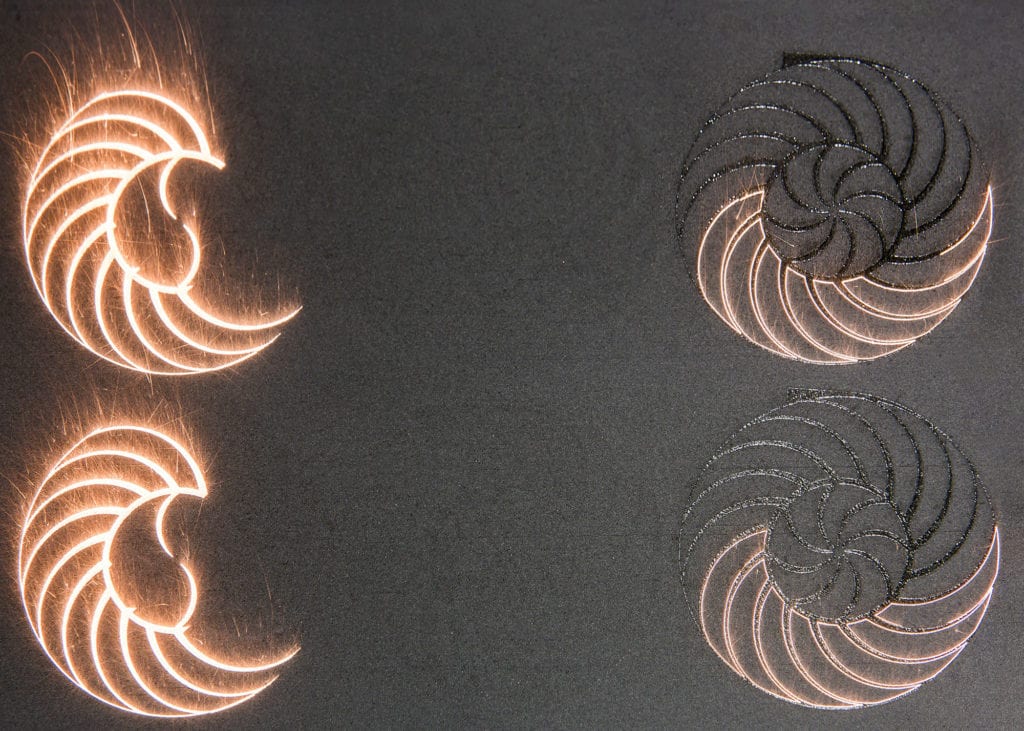

Led by Facility & Upkeep Supervisor Davide Rausa and Additive Manufacturing Chief Dario Mantegazza, the power will function Idea Laser machines with Direct Metallic Laser Melting (DMLM) know-how, enhancing the corporate’s manufacturing capabilities. This growth marks a strategic transfer by Avio Aero to leverage superior additive manufacturing methods for the manufacturing of elements for the GE Catalyst engine.

The GE Catalyst engine, designed with additive manufacturing in thoughts, represents a major milestone in aviation know-how. With over 30% of its elements produced utilizing additive methods, the engine affords improved effectivity and decreased weight, contributing to enhanced plane efficiency.

Collaboration between Avio Aero and GE Additive underscores the trade’s dedication to innovation and technological development. The brand new facility in Brindisi will play an important function in advancing additive manufacturing methods, supported by the Italian authorities’s recognition of additive manufacturing as a key enabling know-how.

As Avio Aero continues to spend money on cutting-edge additive manufacturing know-how, the aerospace trade can anticipate additional developments in plane design and manufacturing, pushed by a dedication to excellence and innovation.

Come and tell us your ideas on our Fb, X, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.