AM Effectivity, a Swedish firm specializing in post-processing options for additive manufacturing, has launched UNPIT, an automatic machine designed for entry-level Selective Laser Sintering (SLS) 3D printers. Making its debut at Formnext 2024 in Frankfurt this November, the brand new machine automates key levels of post-processing—unpacking, depowdering, cleansing, and materials restoration—and is able to reclaiming as much as 100% of unused powder. This function marks a major development in lowering materials waste and reducing operational prices for small and medium-sized enterprises (SMEs) engaged in 3D printing.

Suitable with widespread SLS printers from manufacturers like Sinterit, Sintratec, and Formlabs, UNPIT integrates seamlessly into current workflows. Customers merely place their printed half muffins into the machine, which then completes your entire post-processing sequence with out additional intervention. This automation minimizes guide labor, reduces the associated fee per half, and enhances total manufacturing effectivity.

The event of the brand new system concerned collaboration with Siemens, leveraging their experience in automation and digitalization to boost the machine’s capabilities. This partnership was essential in attaining the excessive degree of automation and effectivity that UNPIT presents, guaranteeing that the machine meets the rigorous calls for of recent additive manufacturing processes.

“We developed UNPIT to handle the bottlenecks within the post-processing part of SLS 3D printing,” stated Casper Rosén, CEO of AM Effectivity. “By automating these steps, corporations can focus extra on their core actions and innovation, fairly than being slowed down by time-consuming guide duties.”

Shipments are scheduled to start in early 2025, following its official launch at Formnext 2024. AM Effectivity anticipates that the machine will likely be well-received by entry-level SLS customers in search of to optimize their post-processing workflows and cut back materials prices.

Trade Strikes In direction of Automated Publish-Processing

The introduction of UNPIT aligns with a broader pattern in additive manufacturing in direction of automation. Rivelin Robotics, a UK-based agency specializing in post-processing for steel 3D printed elements, is main a government-funded venture often called Mission CAMPFIRE to ship automated ending for aerospace elements, orthopedic implants, and fuel turbine elements. Collaborating with corporations like Attenborough Medical and GKN Aerospace, Rivelin’s Netshape Robots use 3D imaginative and prescient and power management algorithms to reduce human enter in post-processing duties.

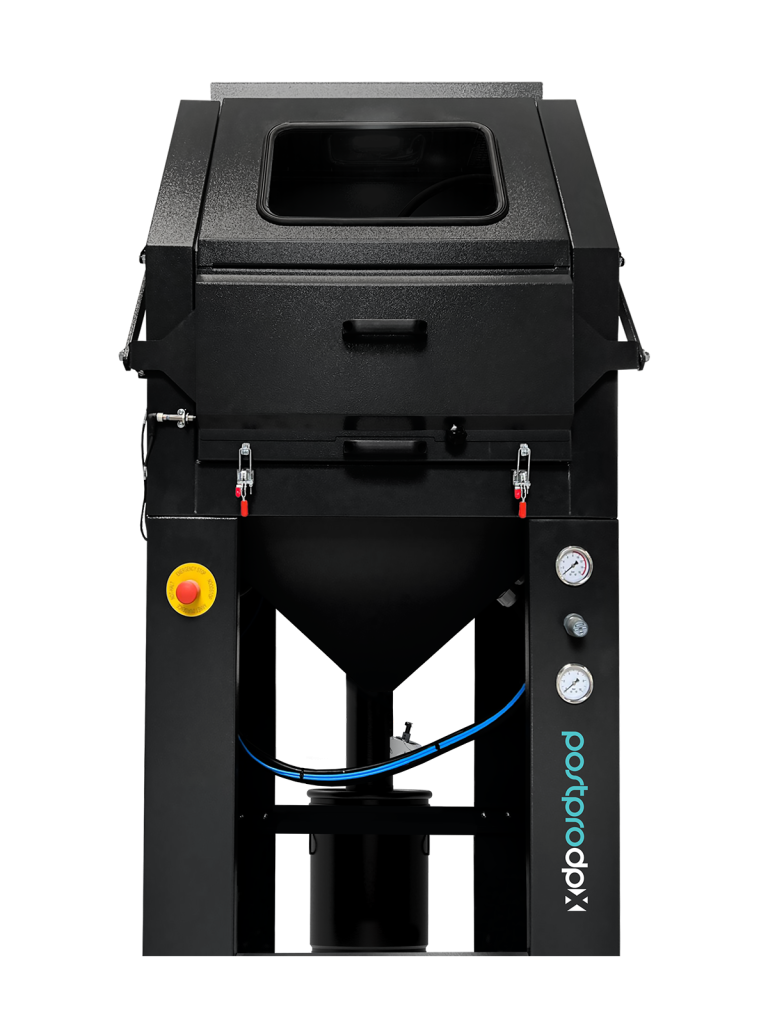

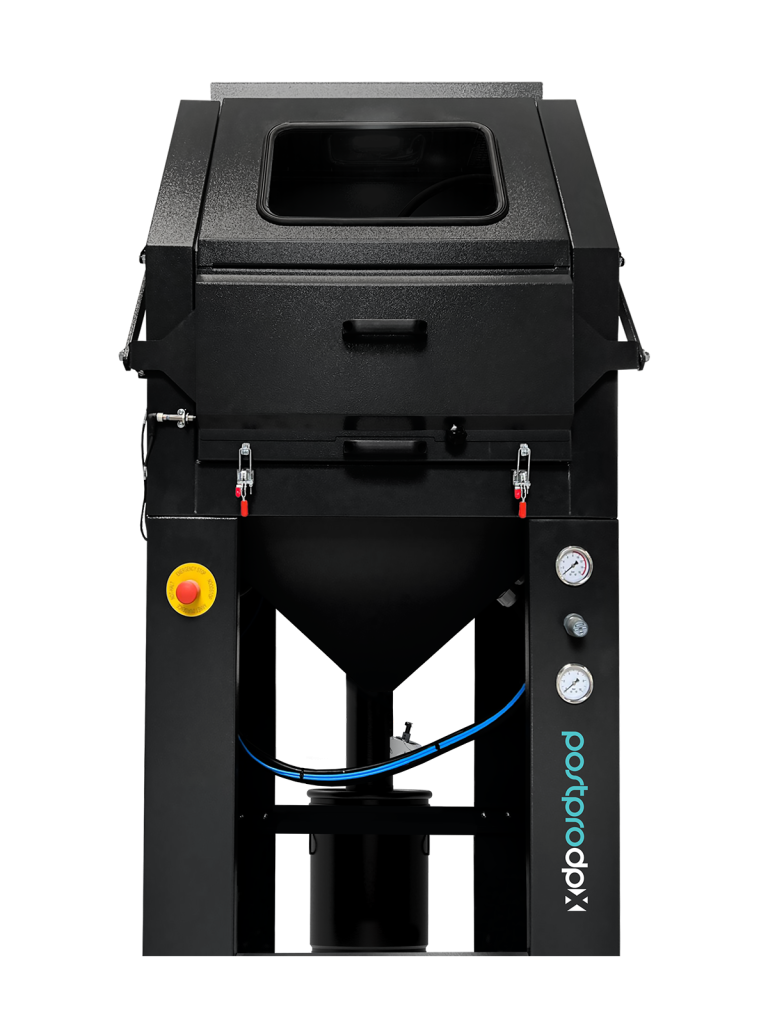

Equally, Additive Manufacturing Applied sciences (AMT) just lately launched the PostPro DPX, a depowdering system aimed on the non-industrial 3D printing market. Priced at €15,995, the DPX enhances desktop 3D printers from manufacturers equivalent to Formlabs and Sinterit. The system presents automated depowdering, a compact design, and superior filtration, catering to industries like dental, jewellery, and prototyping that require environment friendly post-processing options.

Your voice issues within the 2024 3D Printing Trade Awards. Vote Now!

What is going to the way forward for 3D printing appear to be?

Which latest developments are driving the 3D printing trade, as highlighted by specialists?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.Keep related with the newest in 3D printing by following us on Twitter and Fb, and don’t overlook to subscribe to the 3D Printing Trade YouTube channel for extra unique content material.

Featured photos showcase The brand new AM Effectivity UNPIT and UNPIT Brand. Photographs through AM Effectivity.