Italy-based 3D printing firm CRP Expertise will probably be exhibiting its orthoses crafted from Glass Fiber fiber-reinforced thermoplastic Windform GT materials on the SuperPower Design exhibition.

The exhibition will probably be held from March twenty fourth to August twenty fifth, 2024, on the Centre for Innovation and Design (CID) in Grand-Hornu, Belgium. Featured within the displays are orthoses tailor-made for drop foot and hand impairments, developed in collaboration with medical consultants and generative design studio MHOX.

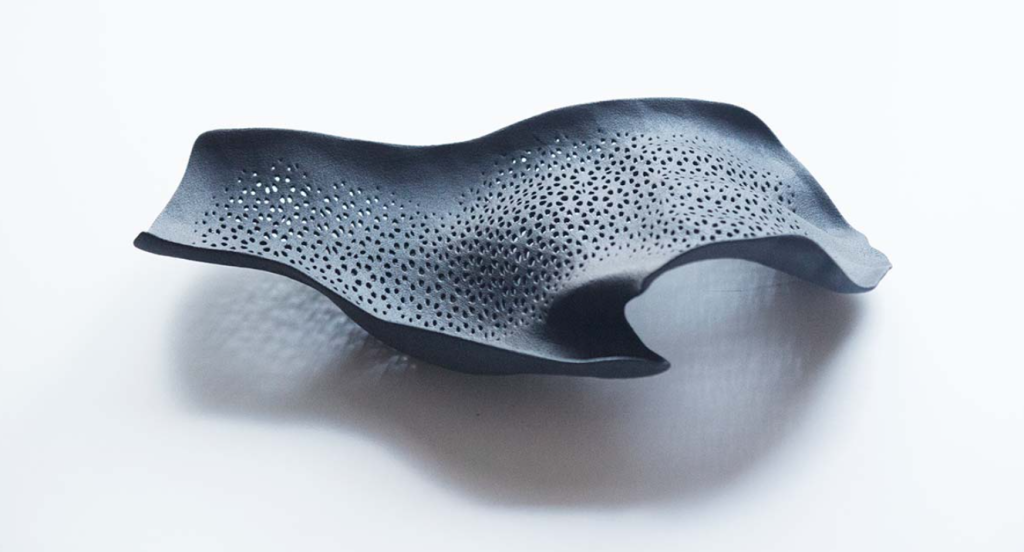

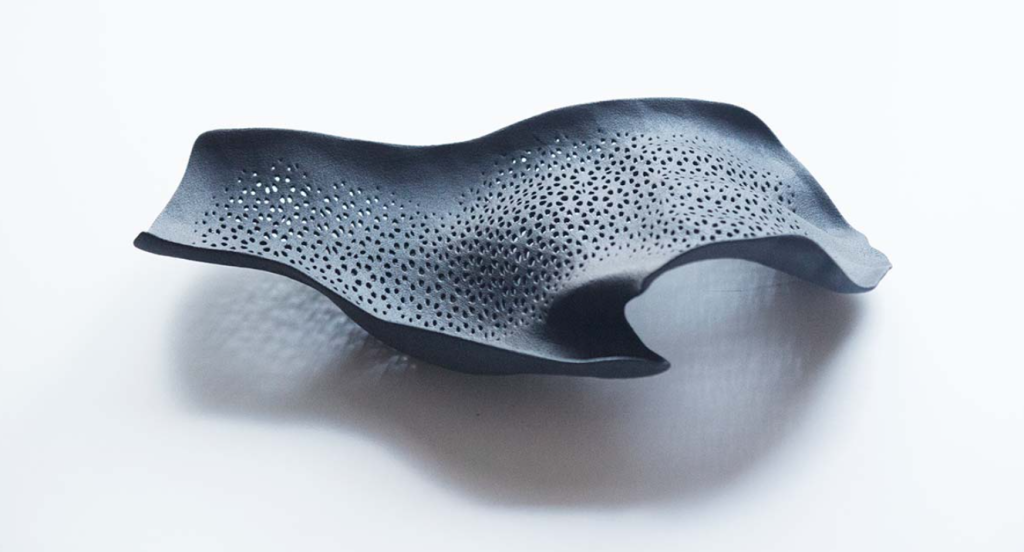

3D printed orthoses

Orthoses are medical units designed to help, align, appropriate, or enhance the perform of components of the physique. They’re typically used to alleviate ache, present stability, or help with motion. Final month, steel AM firm AddUp collaborated with Anatomic Implants for an FDA 510(Okay) software on a novel 3D printed toe joint substitute.

Using titanium printing, Anatomic develops a metatarsophalangeal joint substitute mimicking human anatomy. AddUp’s FormUp 350 powder mattress fusion (PBF) 3D printing system helps regulatory approval, guaranteeing advanced lattice constructions for medical units. The porous construction of the implant encourages osseointegration, promising higher affected person outcomes, says the corporate.

In January 2023, prosthetic specialist Open Bionics supplied 3D printed bionic arms to a German facility treating injured Ukrainian troopers with landmine accidents. Managed by forearm sensors, the Hero Arm presents movable thumb and fingers for enhanced greedy. Recipient Vitalii Ivashchuk praises its performance, expressing gratitude for the machine’s day by day use, citing a “very cool feeling” with its becoming.

Elsewhere, French 3D printing service supplier Sculpteo partnered with Swiss orthopedic specialist Daniel Robert Orthopedie to create an eco-friendly orthosis. Using Sculpteo’s bio-based PA11 materials, the wearable was each sustainable and customizable for sufferers.

Improvements with CRP Expertise

The event course of for these customized orthoses is characterised by three distinct phases. Initially, MHOX, in alliance with CRP Expertise and medical consultants, undertook the duty of scanning the affected person’s physique to generate a exact 3D mannequin of the orthosis. This was adopted by way of proprietary software program developed by MHOX to allow automated customization of the orthoses, tailor-made to the person’s particular wants and anatomy.

Within the essential third stage, CRP Expertise utilized Selective Laser Sintering (SLS) alongside Windform GT materials to manufacture the orthoses by way of 3D printing. Windform GT, a polyamide-based composite strengthened with glass fiber, presents excellent attributes fitted to purposes necessitating flexibility, sturdiness, and affect resistance. Its distinct properties render it extremely acceptable for generative orthoses, prioritizing reliability and longevity.

Apart from medical use, CRP Expertise’s supplies had been leveraged by different sectors. For instance, CRP Expertise collaborated with UAE-based Orbital House for the Lunaris Moon Mission, using 3D printing, particularly PBF. Utilizing Windform’s high-performance composite supplies, this partnership aimed to supply useful parts for the lunar payload. Orbital House believes CRP’s experience will guarantee success in reaching its mission to create space accessible, fostering innovation in aerospace exploration.

The leisure business noticed CRP Expertise work with Michael Mann’s movie manufacturing group for the film “Ferrari,” to craft 3D printed parts like driver helmet components and pit components utilizing Windform supplies and Selective Laser Sintering (SLS). Commissioned throughout filming in Modena, these props enhanced the visible narrative of Enzo Ferrari’s world.

What are the 3D printing traits the business leaders anticipate to see this 12 months?

What does the Way forward for 3D printing maintain for the following 10 years?

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a collection of roles within the business.

Featured picture exhibits 3D printed orthoses made in collaboration with Mhox. Picture by way of CRP Expertise.