Chicago-based 3D printing high quality assurance software program developer Phase3D has introduced the commercialization of its new True Layer Thickness toolkit on the Additive Manufacturing Customers Group (AMUG) 2024 convention in Chicago, operating from March 10-14.

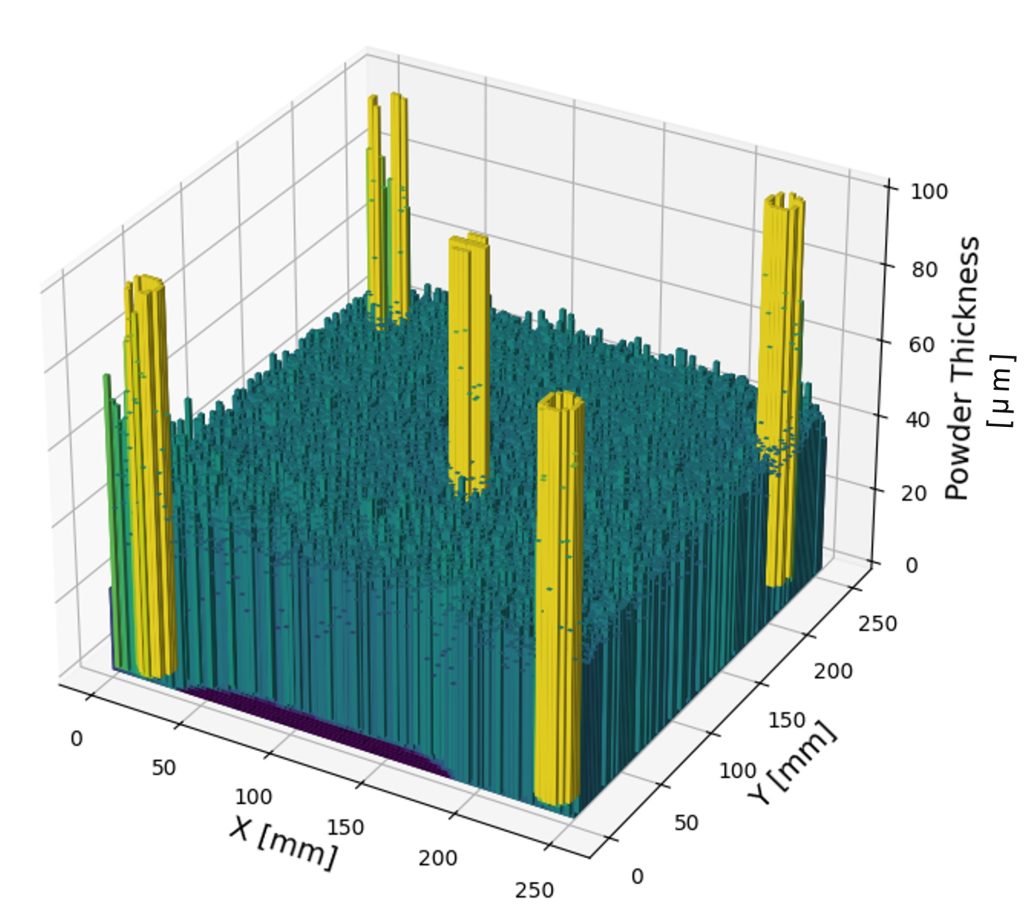

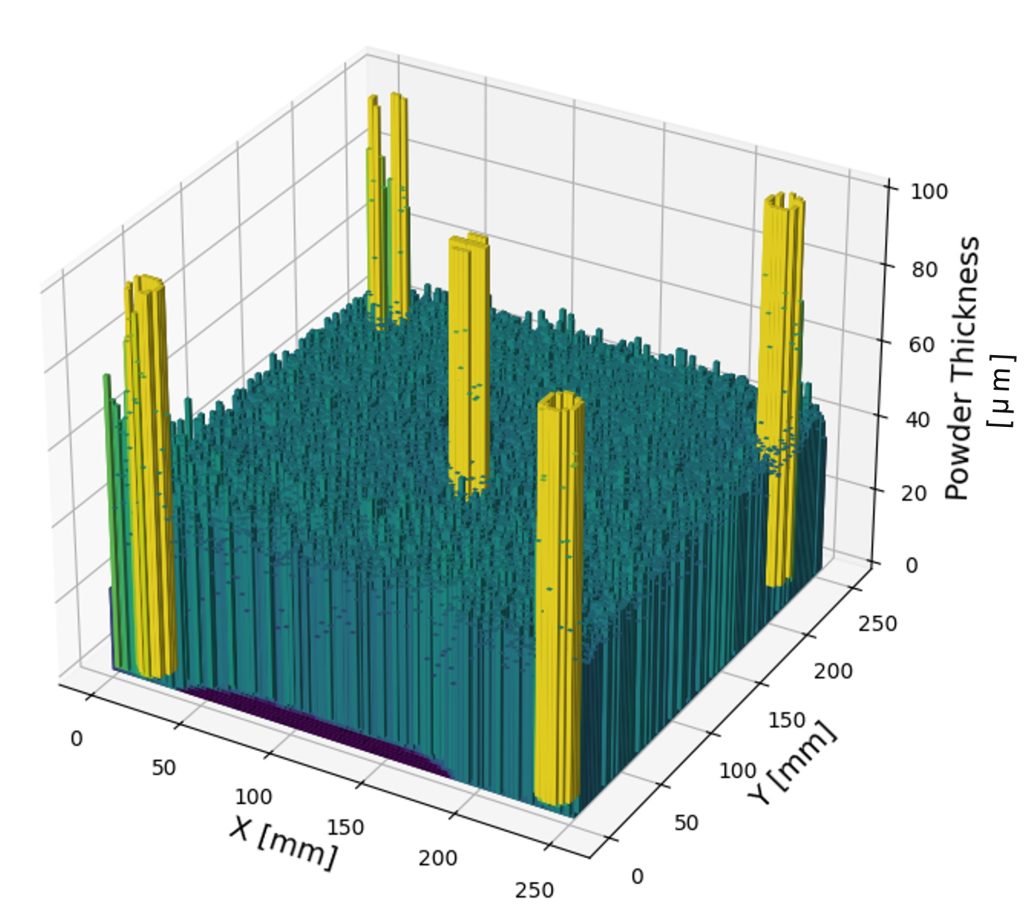

This new monitoring and inspection instrument measures, in microns, the amount of steel powder distributed throughout a 3D printer’s construct platform. This helps customers to make sure a good materials distribution for every layer through the powder mattress fusion 3D printing course of.

The brand new providing seeks to handle the vital wants of corporations inside regulated industries akin to aerospace, medical, and vitality to make sure the constant manufacturing of high-quality and certifiable steel components. Phase3D reportedly developed True Layer Thickness in collaboration with an unnamed ‘outstanding aerospace firm.’

“We’re happy to introduce True Layer Thickness. This new toolkit underscores our dedication to advancing AM for the good thing about widespread adoption of the expertise for vital use functions,” commented Dr. Niall O’Dowd, CEO and Founding father of Phase3D.

Phase3D releases True Layer Thickness toolkit

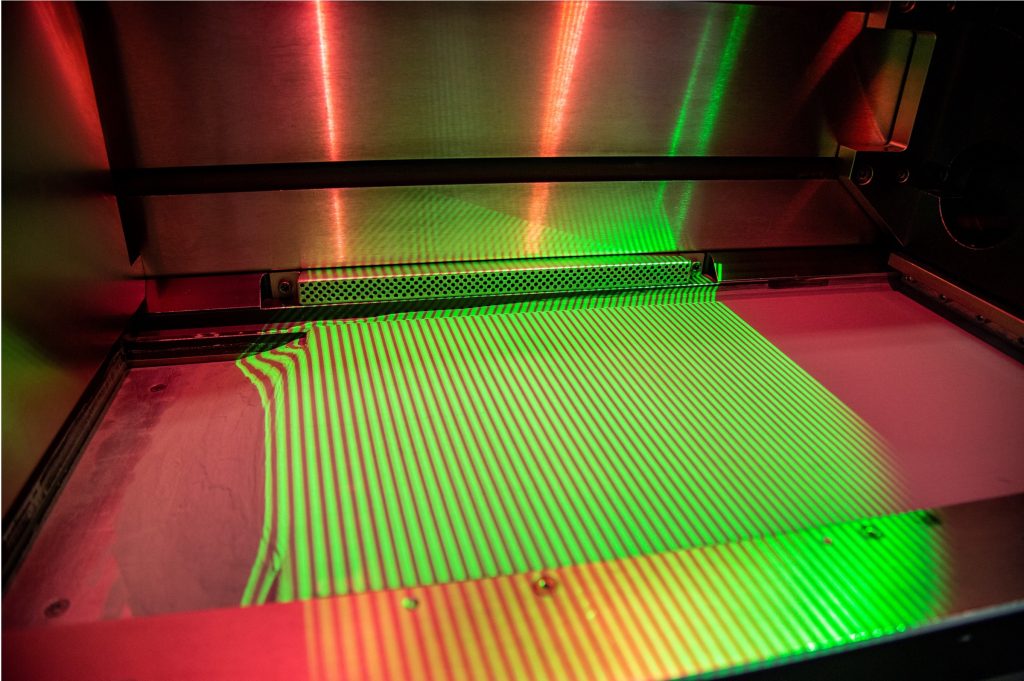

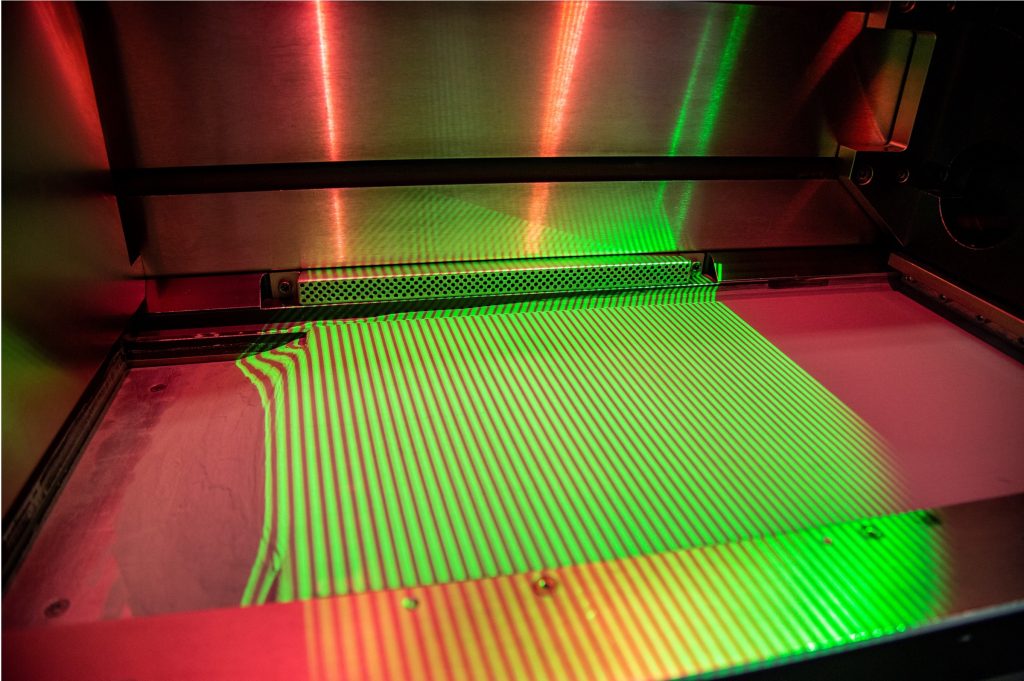

True Layer Thickness has been designed to combine with Fringe, Phase3D’s proprietary monitoring system for steel additive manufacturing. This expertise permits for on-demand inspection of components as they’re 3D printed.

In an interview with 3D Printing Trade, O’Dowd defined that this technique makes use of structured gentle to measure a top map of every materials layer each earlier than and after melting in powder mattress fusion 3D printers. This creates reside 3D visualizations of any height-based anomalies, permitting customers to “make knowledgeable selections about construct cancellation.”

These anomalies could be attributable to recoater streaks, quick feeds, or the uneven distribution of steel powder. Such points can in the end end in an absence of fusion, keyhole porosity, and different issues with the 3D printed half. Subsequently, Fringe can enhance 3D printer utility, scale back waste, and reduce the motion of faulty components into post-inspection processes.

True Layer Thickness creates quantifiable measurements of the unfold of powder throughout 3D printing. Designed to be built-in with Fringe, Phase3D’s new toolkit can be utilized with most PBF 3D printers presently in the marketplace. The brand new providing is tailor-made to handle challenges inside industrial functions related to the aerospace, protection, vitality, and medical sectors.

Phase3D believes that the launch of True Layer Thickness marks a key step within the objective of attaining the repeatable manufacturing of components that meet stringent industrial certification necessities.

The brand new toolkit could be considered first-hand at Sales space 101 in Salon D at AMUG 2024.

High quality management for steel AM

High quality assurance is essential to steel 3D printing, enabling substantial time and value financial savings for these concentrating on the manufacturing of industrial-scale, certifiable components. In 3D Printing Trade’s survey on 3D printing traits to count on in 2024, business specialists highlighted the growing significance of half high quality in additive manufacturing.

Final yr, 3D printing software program and companies firm Materialise launched its AI-powered Course of Management software program for steel 3D printing. This instrument allows companies to regulate the standard of their components through the use of layer information collected throughout 3D printing.

By analyzing and correlating this data, customers can find problematic components earlier than post-processing and high quality inspection phases, which may add 30% to 70% to the prices of a ultimate half. Utilizing synthetic intelligence (AI) and machine studying, Course of Management automates the layer analysis course of, saving time and lowering the affect of human error.

Materialise labored with Phase3D and Sigma Additive Options to develop this providing, combining their supplementary information to attain a complete understanding of the 3D printing course of. Sigma Additive Options’ expertise offers warmth information from the soften pool, the area the place materials is melted throughout 3D printing.

Elsewhere, Californian steel 3D printer producer Velo3D provides its Guarantee High quality Assurance and Management System for its laser powder mattress fusion (LPBF) Sapphire 3D printers.

This software program displays the steel 3D course of, detecting any defects as they happen in addition to offering high quality management and construct report summaries. Leveraging reside, multi-sensor, physics-based detection algorithms, the software program may also hint half high quality throughout 3D printing, streamlining the 3D printed-part validation course of.

What does the way forward for 3D printing maintain?

What near-term 3D printing traits have been highlighted by business specialists?

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals Phase3D’s Fringe structured gentle in-situ monitoring expertise. Photograph by way of Phase3D.