Supernova, a carve-out of Spanish 3D printer producer BCN3D, has launched its new Pulse Manufacturing Platform for high-viscosity resins. The corporate has additionally unveiled Viscogels, a proprietary portfolio of photopolymer supplies providing superior mechanical properties to competing resins.

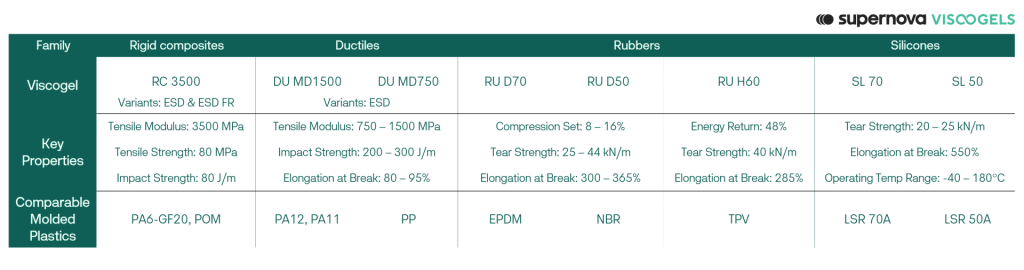

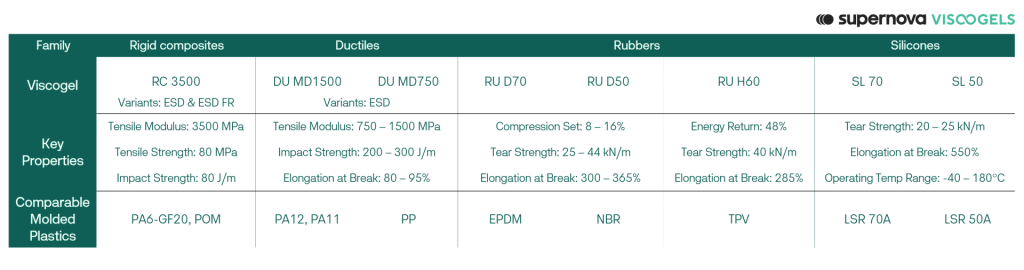

The brand new platform options the Pulse One Viscous Lithography Manufacturing (VLM) 3D printer, Pulse Postprocessing Cell, and Pulse Management Middle software program. This end-to-end manufacturing suite is appropriate with the corporate’s Viscogels lineup, which options twelve completely different supplies spanning 4 photopolymer households (inflexible composites, ductile supplies, rubber, and silicone).

Supernova claims its new merchandise will cut back tooling prices, enhance customization capabilities, and improve 3D printing productiveness for batch manufacturing of end-use elements. Moreover, Viscogels reportedly cut back emissions of poisonous unstable natural compounds (VOC) throughout 3D printing, addressing a rising problem within the resin 3D printing market.

In the course of the on-line launch occasion, Supernova’s CEO Roger Antunez outlined the corporate’s efforts to counter the rising market share of emergent Chinese language 3D printer producers. Based on CONTEXT’s newest 3D printing market figures, skilled customers are more and more adopting low-cost, Chinese language-made 3D printers from the likes of Creality and Bambu Lab. The latter registered 336% YoY cargo progress in Q2 2024.

Antunez shared his considerations that almost all Western additive manufacturing firms have in the reduction of on R&D funding, whereas “actual breakthroughs typically come from China.” He added that “Western firms are being worn out by these Chinese language new gamers” which provide “higher expertise and very low costs.”

To fight this, Supernova is bolstering its R&D initiatives and growing viscous supplies that match the properties of typical injection molding. Antunez believes this “supplies first” strategy will speed up the adoption of its VLM additive manufacturing expertise, unlocking industrial-grade elements at low prices.

“We’re on a mission: to make unimaginable plastic molding runs attainable,” added Antunez. “We’re breaking via limitations to allow clients to provide industrial-grade elements with superior properties, whereas remaining cost-efficient no matter manufacturing quantity.”

Viscogels and the Pulse Manufacturing Platform will start transport in Fall 2025. Supernova will showcase its new merchandise subsequent week at Formnext 2024 in corridor 11.0, sales space D62J.

Viscogels: a brand new high-viscosity resin portfolio

Supernova has labeled its Viscogels into 4 materials households. The Inflexible Composites household is akin to glass-filled PA6, ABS and Polymethyl methacrylate (PMMA). These supplies are designed to offer power, stiffness and dimensional stability.

The Ductile household resembles polypropylene, PVC and PA11. These formulations reportedly supply high-impact resistance and elongation earlier than breaking.

The Rubber Viscogels household seeks to satisfy extra versatile wants. They function excessive tear power and elasticity, matching the efficiency of EPDM, gentle TPUs and TPEs.

Lastly, the Silicone household mirrors silicone rubbers. They provide resistance to temperatures starting from minus 60℃ to over 200℃.

Viscogel supplies are extremely viscous, with formulations beginning at 20,000 cP and a few reaching over 1 million cP. Standard resin 3D printers, alternatively, usually course of photopolymer supplies under 1000 cP.

The excessive viscosity of Viscogels is achieved by formulating the supplies with not less than 80% oligomers, 4 instances greater than typical 3D printing resins. This reportedly permits the 3D printable supplies to rival the tensile power, impression resistance, and temperature resistance of molded plastics akin to PA6, Polypropylene (PP), EPDM, and liquid silicone rubber.

Due to their excessive viscosity, Viscogels can incorporate greater loadings of strong components like ceramics and metals with out compromising processability. They’re additionally appropriate with a greater diversity of additive shapes, additional enhancing the power and sturdiness of 3D printed elements.

Based on Robert Younger, Supernova’s Director of Supplies, water absorption and chemical resistance are “the most important challenges that forestall the adoption of photopolymer additive manufacturing.”

Low-viscosity resins create a porous construction, permitting liquids and chemical substances to be absorbed into the fabric, which damages the properties of 3D printed elements. The excessive oligomer content material of Viscogels combats this, making a denser polymer matrix which is much less porous. As an example, Supernova’s new supplies exhibit a water absorption of lower than 0.5%.

Viscogels additionally considerably cut back emissions of VOCs, that are dangerous to people. The potential well being results of those chemical substances vary from complications and nausea to kidney harm and most cancers.

In photopolymer 3D printing, VOC emissions are primarily attributable to monomers inside the resin materials. Younger defined that some monomers can turn out to be trapped within the polymer matrix throughout curing. These uncured monomers migrate to the floor of the 3D printed half and launch into the air.

Viscogels possess a decrease monomer content material in comparison with conventional low-viscosity photopolymers. This reportedly ensures that extra monomers totally treatment inside the materials, considerably decreasing VOC emissions. Younger added that this permits Viscogels to satisfy strict business necessities, guaranteeing “safer, cleaner and extra sustainable finish elements.”

Supernova’s new end-to-end manufacturing platform

As a result of their extraordinarily excessive viscosity, Viscogels can solely be processed utilizing Supernova’s VLM expertise. To 3D print these supplies, Supernova has developed its Pulse Manufacturing Platform, incorporating a brand new 3D printer, post-processing unit, and software program.

The Pulse One VLM 3D printer options an XY decision of 46µm, a construct quantity of construct quantity of 350 x 200 x 300 mm, and a Z decision vary of fifty – 200μm. It may reportedly obtain a throughput of 5 kg/hour, supporting batch manufacturing purposes.

The Pulse One is exclusive inside the resin 3D printing house attributable to its dual-material 3D printing capabilities. It may concurrently mix two supplies in a single layer for multi-material elements, or 3D print a secondary assist materials. VLM is at the moment growing a totally water-soluble assist materials to automate the assist removing course of.

Supernovas’ Pulse Postprocessing Cell is an automatic post-processing unit which washes and cures elements 3D printed on the Pulse One. It may reportedly course of as much as 24 builds per day and employs thermal and UV curing to attain optimum mechanical properties. The cell boasts automated high quality management at every step, guaranteeing all 3D printed batches are processed appropriately. Moreover, RFID monitoring ensures traceability all through the workflow.

This traceability and high quality management, together with construct preparation and slicing, is managed by the Pulse Management Middle software program. This platform reportedly ensures half repeatability by monitoring the manufacturing course of. Its algorithm can detect defects through the 3D printing course of and mechanically make corrections to take care of excessive manufacturing requirements.

Developments in resin 3D printing

Supernova’s Viscogels are the newest 3D printing resins to enter the additive manufacturing market.

Final month, 3D printing supplies producer polySpectra launched Cyclic Olefin Resin (COR) Zero, its new manufacturing-grade resin that can be utilized with inexpensive 3D printers. The corporate claims that this materials brings industrial-level manufacturing capabilities into residence workshops and small companies.

COR Zero reportedly presents a cheap different to injection molding for makers, designers, and engineers. It’s optimized for purposes like mechanical elements, fluidic elements, digital enclosures, and wearables akin to glasses and podiatry inserts. The resin additionally seeks to sort out widespread challenges referring to brittleness and thermal instability. Suitable with desktop DLP and LCD 3D printers, COR supplies mix toughness, warmth resistance, and chemical sturdiness. Particularly, it boasts a tensile power of 53 MPa, a modulus of 2175 MPa, and an elongation at a break of 18%.

Elsewhere, Formlabs Dental, the dental enterprise unit of Resin 3D printer producer Formlabs, lately obtained 510(okay) clearance from the US Meals and Drug Administration (FDA) for its Premium Enamel Resin. This permits dental professionals within the US to 3D print dental elements, akin to single items of crowns, inlays, onlays, veneers, and as much as seven-unit non permanent bridges, with the resin.

Launched in January 2024, Premium Enamel Resin is a nano-ceramic-filled biocompatible materials for lifelike dental elements that mimic the translucency and opalescence of pure tooth. The resin is appropriate with Type 3B+, Type 3BL, and Type 4B 3D printers, and has additionally been cleared to be used within the EU, UK, Switzerland, and Canada.

Learn all of the information from Formnext 2024.

Who’re the leaders in additive manufacturing? Vote now within the 2024 3D Printing Trade Awards!

Wish to share insights on key business traits and the long run 3D printing? Register now to be included within the 2025 3D Printing Trade Government Survey.

What does the way forward for 3D printing maintain? What near-term 3D printing traits have been highlighted by business specialists?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You may as well comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals Supernova’s Pulse One 3D printer. Picture through Supernova.