Austrian ceramic 3D printing firm Lithoz will current the subsequent improvement stage of its lithium disilicate materials for dental 3D printing at LMT Lab Day Chicago 2024.

The fabric has been Collectively developed with built-in dental options producer Ivoclar, and relies on the corporate’s IPS e.max lithium disilicate powder. In accordance with Lithoz, this new providing will allow serial manufacturing of patient-specific, natural-looking all-ceramic dental restorations.

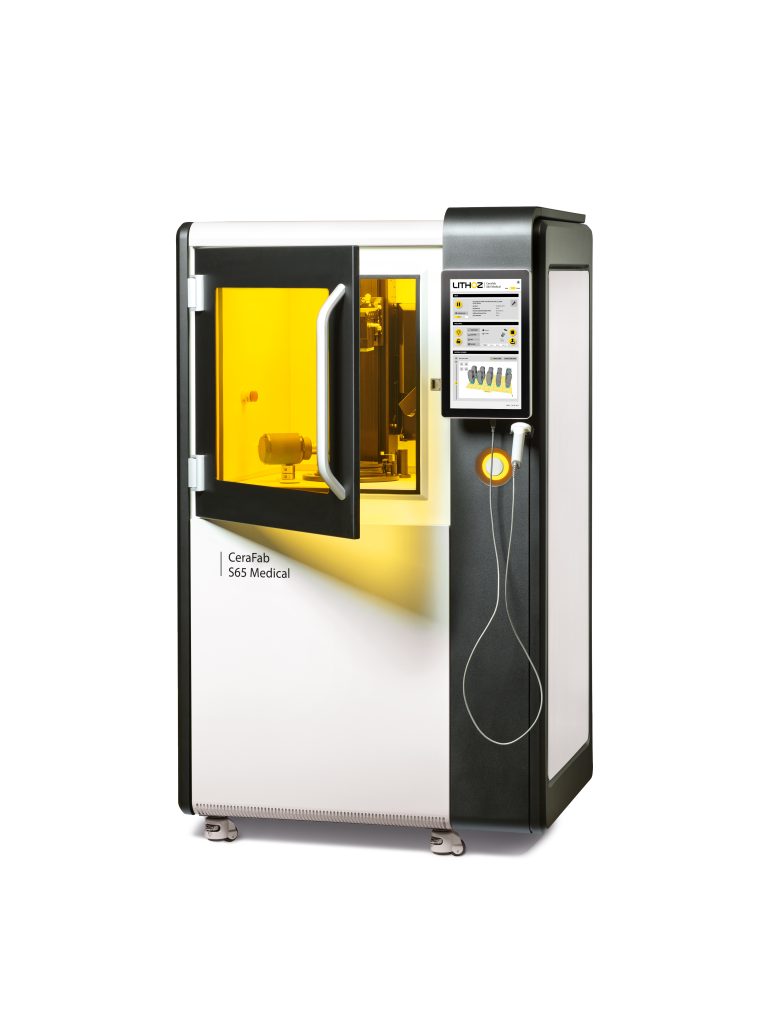

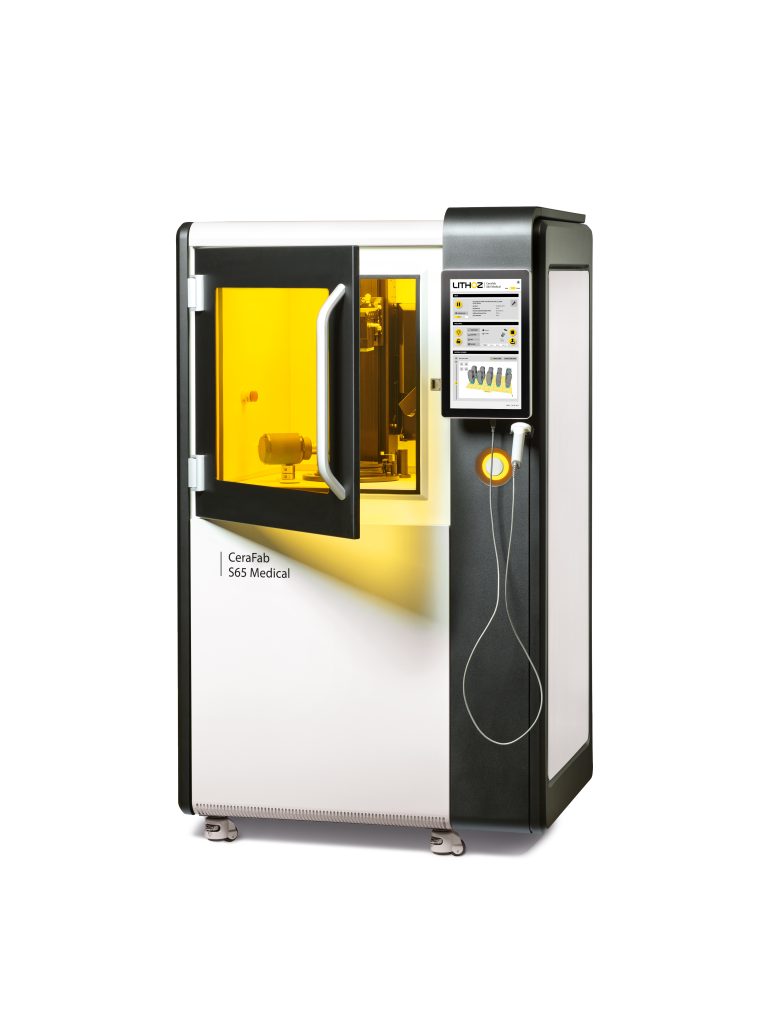

Lithoz can even showcase its Lithography-based Ceramic Manufacturing (LCM) 3D printing course of, which is used to manufacture the dental restorations.

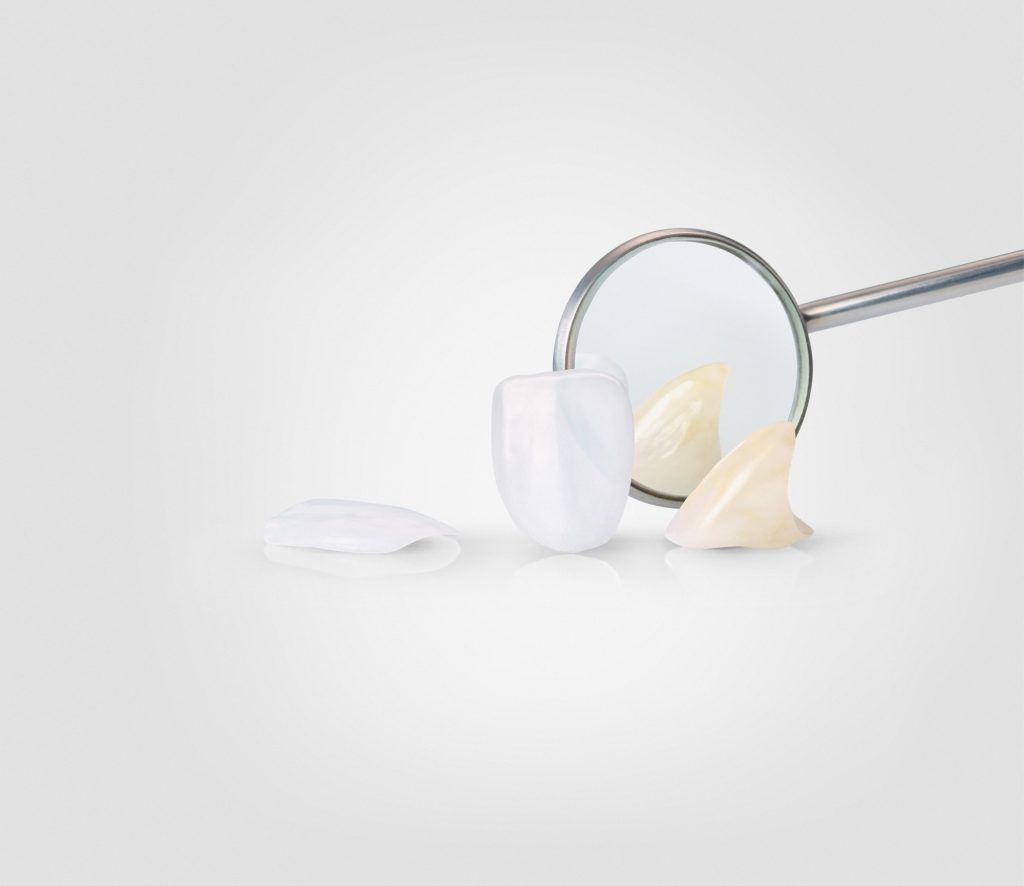

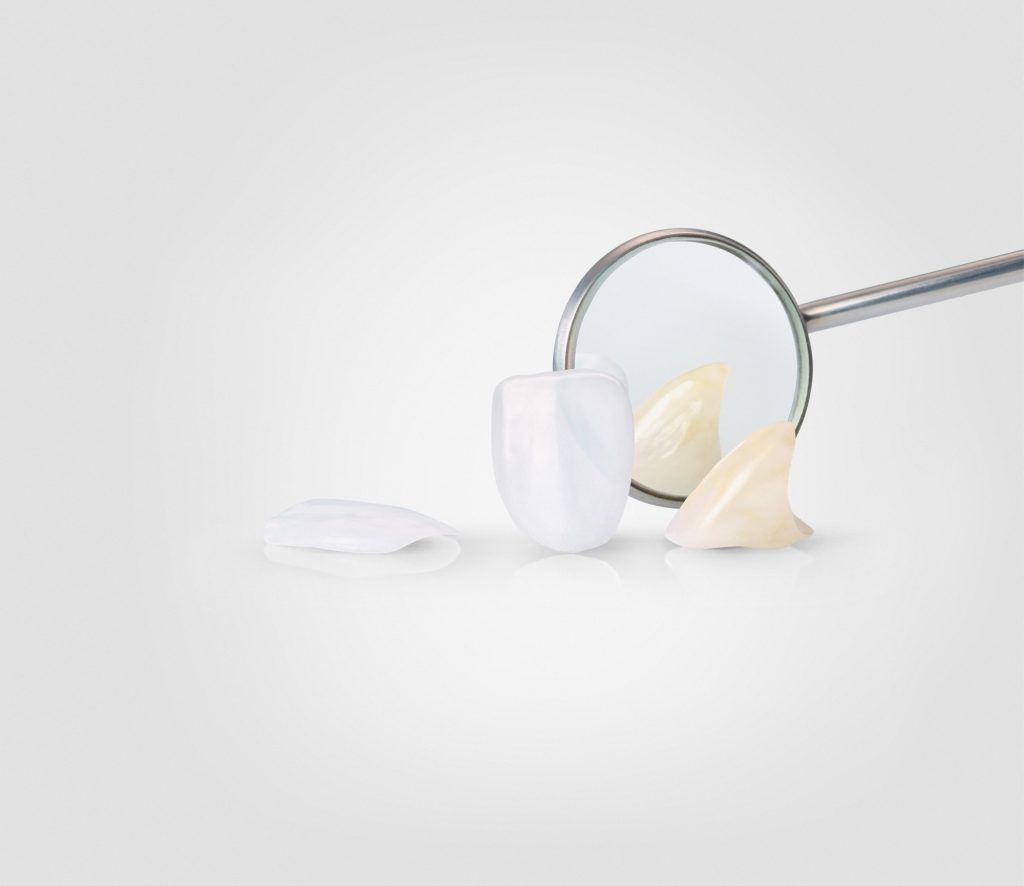

Guests to LMT Lab Day Chicago can view and work together with a spread of lithium disilicate 3D printed veneers and crowns at Lithoz sales space F-24 between 22-24 February 2024.

“With the launch of IPS e.max press 18 years in the past, Ivoclar set a cloth customary for dental restorations which to today has not but been surpassed,” commented Josef Schweiger, Head of Dental Lab, Division of Prosthetic Dentistry, College Hospital LMU Munich.

“With the LCM 3D printing expertise, Lithoz has now reached a brand new milestone within the personalized collection manufacturing of lithium disilicate, which is characterised by its consideration to element, exact match and an easy workflow.”

Scaling dental restoration with Lithoz 3D printing

Lithoz and Ivoclar’s lithium disilicate materials reportedly permits high-quality, patient-specific dental restorations to be 3D printed in collection manufacturing portions.

In accordance with Lithoz, the brand new lithium disilicate materials can be utilized with LCM expertise to 3D print as much as 50 particular person restorations in a single run. As much as 350 restorations can reportedly be produced per day on a single Lithoz CeraFab System S65 Medical 3D printer.

The lithium disilicate dental elements are additionally stated to supply zero materials waste, with 8-fold effectivity in comparison with standard manufacturing strategies. The 3D printed restorations embody veneers as skinny as 0.3mm, and crowns with particulars that precisely signify the options and translucency of pure enamel.

Lithoz claims that the brand new materials providing will “launch a brand new period of unprecedented manufacturing effectivity for giant dental labs.”

At LMT Lab Day Chicago, Lithoz will current LCM 3D printed dental functions, together with patient-specific osteoconductive and bioresorbable mandibular augmentations constituted of hydroxyapatite or tricalcium phosphate. 3D printed dental implants constituted of zirconia (TZP-A) and alumina-toughened zirconia (ATZ) can even be displayed. Guests will have the ability to choose up the elements for a ‘contact and really feel’ expertise.

Daniel Bomze, Director of Medical Options at Lithoz, can even host a free interactive workshop titled ‘3D-Printed Lithium Disilicate Restorations: The Environment friendly Solution to Excellent Dental Aesthetics.’ This presentation, going down on February 23 at 10:45 am, will showcase Lithoz’s new additive manufacturing course of for lithium disilicate dental elements.

Developments in dental 3D printing

In a latest survey on 3D printing developments, 3D printing specialists highlighted that widespread adoption of 3D printing inside the dental business is anticipated to proceed in 2024.

The respondents additionally famous rising personalization within the dental market by way of the usage of 3D printing, with practitioners shifting from oblique manufacturing for mould creation to direct manufacturing of dental gadgets and home equipment.

At Formnext 2023, Axtra3D, Oqton, and 3D Techniques launched a brand new dental resolution focused at assembly advanced necessities of dental laboratories. The collaborative providing combines Axtra3D’s Lumia X1 printer and Hybrid PhotoSynthesis and TruLayer applied sciences, Oqton’s AI-powered automation, and 3D Techniques’ NextDent supplies.

The mixed providing reportedly elevates business requirements by delivering superior floor high quality, excessive throughput, predictive upkeep, and premium supplies for on-site manufacturing in dental labs.

Elsewhere, Israel-based 3D printer producer Stratasys introduced that its professional-grade multi-material DentaJet 3D printer collection is seeing elevated adoption inside the world dental business. This announcement adopted the launch of the corporate’s entry-level J3 DentaJet 3D printer in 2023. This dental 3D printer reportedly provides excessive accuracy for dental functions, while optimizing general manufacturing efficiencies.

One buyer to amass Stratasys’ DentaJet 3D printing expertise is Superior Dental Applied sciences (ADT). This Bostin-based full-service lab bought the J3 DentaJet system to supply its personal crown and bridge, detachable, and implant fashions.

Equally, French dental lab Ident’M bought J5 DentaJet 3D printer. The corporate now runs the 3D printer 20 hours a day to supply round 1,000 dental elements every month.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture reveals veneers and crowns 3D printed with Lithoz and Ivoclar’s lithium disilicate materials. Picture through Lithoz.