On this version of Sliced, the 3D Printing Trade information digest, we cowl the most recent enterprise developments, partnerships, and acquisitions within the additive manufacturing sector.

Right this moment’s version options new supplies, reseller offers, and software program, and professors Denis Cormier and Bey Vrancken awarded for his or her contributions in AM on the SFF symposium.

Learn on for the latest updates from Titomic, Stratasys, 3D Programs, SPEE3D, AML3D, and Roboze.

Nominations for the 2024 3D Printing Trade Awards are actually open. Inform us who’s main.

Enterprise offers and acquisitions from Protolabs, IperionX, Triton Programs, and extra

Beginning with enterprise offers, Protolabs has acquired Axtra3D‘s Lumia X1 3D printer to boost its Additive Manufacturing (AM) workflow. Recognized for its quick and high-quality manufacturing, Protolabs selected the Lumia X1 for its superior velocity, accuracy, and floor end.

This buy permits Protolabs to optimize its providers utilizing BASF Ultracur 3D RG 3280 materials, facilitating the manufacturing of high-performance elements and electrical connectors. This collaboration is predicted to spice up Protolabs’ capability to fulfill rising buyer calls for throughout industries whereas sustaining fast turnaround instances.

Subsequent up, steel 3D printer producers Titomic and Repkon have initiated a three way partnership, beginning with an AUD$2.3 million buy of a TKF 1000 chilly spray system. Situated in Turkey, this facility will combine Titomic’s TKF expertise with Repkon’s flow-forming methods to boost barrel manufacturing.

By doing so, the corporate goals to ship sooner manufacturing instances, lighter supplies, and improved efficiency. This enterprise is vital because it strengthens Titomic’s place within the protection sector and opens new alternatives for exterior prospects utilizing superior manufacturing methods.

Herbert Koeck, Managing Director of Titomic, stated, “We anticipate the finished Facility will present aggressive and novel capabilities for the worldwide protection sector and bolster Titomic’s place as a globally aggressive manufacturing supplier, increasing on Titomic’s repute and agreements with main protection gamers similar to Triton, BAE Programs, Boeing, and Airbus.”

Moreover, Triton Programs has bought a low-pressure D523 System from Titomic for AUD$72,000, additional strengthening their partnership. Acknowledged for its work within the protection and expertise sectors, Triton Programs will use Titomic’s chilly spray expertise to boost its manufacturing capabilities.

This follows the corporate’s latest acquisition of a high-pressure TKF System, reflecting Triton’s concentrate on using each low and high-pressure options. The partnership helps the event of superior manufacturing processes for U.S. industries by means of Titomic’s expertise.

In different information, K3D has turn into the first worldwide buyer for Additive Industries‘ new MetalFab 300 Flex system, ordering two models to develop its steel additive manufacturing (AM) capabilities. Launched on the RAPID + TCT 2024, the MetalFab 300 Flex gives flexibility with a scalable construct space, making it appropriate for numerous functions.

This funding helps K3D’s rising demand throughout industries like aerospace, automotive, and protection, notably for chrome steel and titanium elements. The system permits K3D to extend manufacturing capability whereas minimizing monetary threat by means of scalable options and versatile construct choices.

Mott Company has purchased Renishaw’s RenAM 500S Flex machine to boost its additive manufacturing capabilities for filtration and circulation management parts. The brand new system reduces setup and turnaround instances by over 50% and improves efficiency consistency by 30%.

Its open structure permits for personalisation, enabling Mott to optimize designs for particular functions, supporting industries like aerospace, bioreactors, and semiconductors. This improve accelerates improvement cycles and improves product reliability, increasing Mott’s manufacturing potentialities, says the corporate.

Tekna Holding has secured two orders for its TEK40 plasma techniques, valued at CAD $2.0 million, with supply scheduled over the following 12 months. Recognized for his or her superior capabilities, these techniques will assist analysis and improvement in supplies past Tekna’s common industries. The orders contribute to Tekna’s rising backlog, which now totals CAD $6.2 million, says the corporate.

“We reaffirm our standing because the main supplier of superior plasma techniques to trade and academia. Our refined techniques product line offers a robust basis for Tekna, whereas we proceed to develop our personal manufacturing of superior supplies,” says Luc Dionne, CEO of Tekna.

Cooksongold has launched a brand new industrial division, Cookson Industrial, to advance using valuable metals in additive manufacturing (AM) for performance-critical functions. Targeted on aerospace, healthcare, and glass fiber manufacturing, this division gives end-to-end providers together with consultancy, R&D, and manufacturing, with AM capabilities managed from its Birmingham web site.

By producing valuable steel powders like gold and platinum in-house, Cookson Industrial goals to de-risk improvement, shorten provide chains, and improve efficiency in excessive environments the place conventional alloys fail. Moreover, the corporate has partnered with the College of Birmingham for additional analysis.

North Carolina-based titanium developer IperionX has efficiently commissioned its Hydrogen Assisted Metallothermic Discount (HAMR) furnace on the Titanium Manufacturing Campus in Virginia, reaching its first titanium de-oxygenation manufacturing run.

This improvement boosts titanium manufacturing capability by over 60 instances, with oxygen ranges within the scrap titanium lowered from 3.42% to under 0.07%, surpassing ASTM requirements. IperionX plans to optimize its processes by late 2024, with ambitions to steer U.S. titanium manufacturing at over 10,000 metric tons yearly by 2030, providing a sustainable and cost-effective different to conventional strategies.

Elsewhere, 3D-Gasoline has regained its independence, permitting the corporate to refocus on high quality, reliability, and buyer assist within the desktop 3D printing market. With a renewed emphasis on USA-manufactured and supported FDM supplies, the corporate goals to fulfill the evolving wants of consumers in a quickly rising sector. Well-liked merchandise like Customary PLA+, Powerful Professional PLA+, and Professional PCTG can be found in numerous colours.

Trumpf Ltd, based mostly in Luton, is celebrating 50 years of delivering cutting-edge machine instruments and laser expertise to UK producers. Based in 1974 with a workforce of simply 5 staff, the corporate has expanded to over 100 employees and now operates from a state-of-the-art facility in Luton.

To commemorate this vital milestone, Trumpf held a number of occasions, together with a gala attended by executives from its German guardian firm. The corporate additionally hosted an open home, the place they showcased the most recent improvements in machine device and laser expertise to prospects and companions.

Rising partnerships from Ai Construct, Roboze, Xact Metallic, and extra

Transferring on with the most recent partnership information, software program firm Aibuild has partnered with Hyperion Programs, an Australian large-format 3D printing supplier, to advance AI-driven 3D printing throughout Australia, New Zealand, and Asia.

For this collaboration, Hyperion will combine Aibuild’s AI-powered automation instruments to enhance effectivity and precision in manufacturing. This transfer goals to focus on key industries similar to development, protection, and maritime. By combining their applied sciences, the partnership goals to refine manufacturing processes and improve large-scale 3D printing capabilities in these areas.

Adopted by Built-in Deposition Options (IDS) has partnered with Superior Printed Digital Options (APES) to speed up the event of 3D printed electronics functions, leveraging IDS’s NanoJet expertise. This partnership goals to streamline the product concept-to-production course of for patrons, addressing challenges within the adoption of printed electronics.

By combining IDS’s superior aerosol printing platforms with APES’s engineering and manufacturing providers, the collaboration seeks to align product design with manufacturing capabilities, decreasing complexities and dashing up the event and market entry of next-generation electronics. This integration is vital in industries like biomedical, electronics packaging, and versatile hybrid electronics.

Chip Ganassi Racing (CGR) has partnered with ROBOZE, a 3D printing firm, to boost its motorsport efforts. ROBOZE’s superior polymer supplies and exact 3D printing expertise might be built-in into CGR’s Indianapolis race store, aiming to enhance efficiency and innovation within the INDYCAR SERIES.

This collaboration follows ROBOZE’s partnerships with different motorsport groups and industries, highlighting its position in advancing cutting-edge expertise by means of additive manufacturing. Chris Simmons, Director of Efficiency, CGR stated “Chip Ganassi Racing has been utilizing additive manufacturing for years now, each in-house and outsourced. We’ve been in search of a associate with the precise mixture of efficiency, capabilities, velocity and measurement, and we’re excited to have discovered that associate in ROBOZE.”

Powder mattress fusion 3D printer producer Xact Metallic has partnered with PanOptimization to develop entry to reasonably priced steel 3D printing for small and medium-sized corporations. This partnership integrates PanOptimization’s PanX software program with Xact Metallic’s 3D printing techniques, enabling superior thermomechanical simulation and optimization.

PanX helps determine and proper construct points, enhancing efficiency whereas decreasing trial and error. This integration goals to decrease the price of steel additive manufacturing and enhance system efficiency, providing advantages to industries like injection molding, supported by means of Xact Metallic’s world gross sales community.

New supplies from Vibrant Laser Applied sciences, Tekna, Azul 3D, and extra

Shifting the main target to new supplies, Protolabs has expanded its AM capabilities with the launch of the PAx Pure materials collection, together with PAx Clean Pure and PAx Vapour Clean Pure. These versatile polyamides are designed for SLS processes, providing improved sturdiness, toughness, and suppleness.

As per protolabs, the supplies allow sooner manufacturing as a consequence of decrease printing temperatures. PAx Vapour Clean offers enhanced translucency, perfect for show functions. Each supplies are suited to a variety of industries, together with automotive, medical expertise, and electronics, offering prospects with extra choices for modern prototypes and end-use elements.

Vibrant Laser Applied sciences (BLT) has efficiently mass-produced high-quality BLT-Ti₂AlNb powder for additive manufacturing, a key improvement for industries like aerospace. Recognized for its energy, this alloy high-temperature efficiency, and oxidation resistance, is right for light-weight structural parts.

BLT’s superior atomization expertise ensures constant high quality, enabling the manufacturing of complicated, high-performance elements. This achievement paves the way in which for broader analysis and large-scale functions of Ti₂AlNb in industries that demand high-strength, high-temperature supplies.

Tekna has launched superior Ti64 coarse powders for Laser Powder Mattress Fusion (L-PBF) machines, providing elevated productiveness, cost-efficiency, and security for additive manufacturing. These powders, designed for thicker layer functions, cut back manufacturing time and prices, whereas enhancing mechanical properties.

Utilizing Tekna’s plasma atomization expertise with this materials ensures high-density, spherical powders, that are simpler to deal with as a consequence of decrease oxygen sensitivity. The powders meet trade requirements and are notably helpful for industries in search of financial and security enhancements, marking a key development within the additive manufacturing market.

Illinois-based 3D printer producer Azul 3D has launched POND, a small-scale 3D printing system designed to speed up materials and utility improvement for its proprietary HARP expertise. This strategic launch goals to assist companions quickly determine and commercialize disruptive 3D printing functions.

Based on the corporate, POND gives high-resolution printing with a liquid-liquid interface, offering steady printing and full thermal management. The system is vital for analysis, as demonstrated by Sandia Nationwide Laboratory, which is utilizing it to develop embedded electronics in printed parts.

6K’s AM division 6K Additive has expanded its product portfolio by introducing angular chromium (Chrome 99.95% Powder, Chrome 99.8% Powder, Chrome 99.5% Powder, and AT Chrome 99.5% Powder) and titanium (Titanium HDH Powder, Titanium Hydride Powder, and Titanium Sponge Powder) powders, addressing rising demand throughout industries similar to aerospace, power, and manufacturing. These powders are utilized in functions like thermal spray, steel injection molding, and additive manufacturing.

With the acquisition of GMP, 6K Additive has enhanced its sustainable manufacturing and recycling capabilities. Famous for his or her excessive purity, these angular powders meet rigorous high quality requirements and open new markets, providing prospects extra sustainable and high-performance materials choices.

Portuguese filament producer Filkemp has launched a brand new line of PLA filaments tailor-made for the maker section of the 3D printing trade, emphasizing sustainability and lowered carbon emissions. This transfer aligns with the corporate’s dedication to environmental accountability, aiming for NET zero emissions by 2030.

The PLA packaging is created from 95% recycled supplies, highlighting Filkemp’s concentrate on high quality and sustainability for eco-conscious shoppers. Moreover, the corporate has taken steps to scale back its carbon footprint by switching to native suppliers and utilizing renewable power.

Sturdy protection contributions from SPEE3D, AML3D, Meltio, and Titomic

Specializing in the protection sector, SPEE3D has introduced the conclusion of Trident Warrior, the experimental portion of the Rim of the Pacific (RIMPAC) train – on the Marine Corps Air Station in Kaneohe Bay in Hawaii. The corporate deployed its Expeditionary Manufacturing Unit (EMU), a cell 3D printing resolution.

Utilizing chilly spray additive manufacturing (CSAM), SPEE3D printed 11 cast-equivalent steel elements for protection tools on-site. The goal was to reveal how additive manufacturing might cut back the time for repairing or changing vital navy elements, supporting provide chains in contested environments. This train underscored the potential of 3D printing in enhancing navy readiness.

“SPEE3D is thrilled to be included in RIMPAC, the most important distributed superior manufacturing demonstration the Division of Protection has ever performed thus far,” stated Byron Kennedy, CEO of SPEE3D. “Particularly, additive manufacturing has been a significant space of curiosity for the Division of Protection (DoD), and collectively, we have now the identical targets to coach the navy and implement additive manufacturing to print essential steel elements on the level of must assist modernization and warfighter readiness.”

Australian large-format 3D printer producer AML3D has supplied an replace on its collaboration with Boeing in its This autumn report, highlighting the finalization of a Defence Manufacturing License Settlement (MLA) with Boeing Defence and House and its Australian subsidiaries.

This settlement permits AML3D to assist additive manufacturing, testing, and inspection of plane elements, whereas complying with US Authorities laws for Worldwide Visitors in Arms Rules (ITAR) contracts. The MLA builds on earlier collaborations, similar to supplying aluminum take a look at elements and 3D printed tooling parts, and positioning AML3D for additional growth within the aerospace and protection sectors.

Moreover, AML3D has acquired an AUD$0.28 million order from Century Engineering to improve its robotic welding system to an ARCEMY steel 3D printing system. This modernization will improve Century Engineering’s capabilities within the Australian Defence, Mining, Energy, and Water industries. The deal helps AML3D’s technique to develop ARCEMY gross sales into extra markets, together with protection and industrial sectors past the US.

Furthermore, AML3D has commissioned its AUD$2.5 million ARCEMY ‘X-Version 6700’ 3D printing system for US protection contractor Cogitic Company. Now operational, the system will produce steel parts for the US Navy’s submarine base, aligning with AML3D’s technique to develop within the US protection sector. The partnership additionally opens alternatives to provide Cogitic’s different purchasers within the aerospace, oil, and fuel industries.

AML3D Managing Director Sean Ebert stated, “The profitable commissioning of this Cogitic ARCEMY X system advances a key goal of AML3D’s US scale-up technique, embedding our WAM expertise within the provide chains for the US protection trade and particularly US Navy’s submarine industrial base. AML3D lately established a US Headquarters and manufacturing hub, in Ohio, to maximise alternatives for ARCEMY system and part manufacturing and testing gross sales to the US protection sector.”

Lastly, AML3D has signed a Manufacturing License Settlement (MLA) with Blue Forge Alliance, designed to broaden its involvement in producing 3D printed parts for the US Navy’s submarine program. By this settlement, AML3D will acquire entry to technical knowledge and assist from the Navy, enabling it to check, validate, and manufacture a larger number of submarine elements utilizing its ARCEMY Wire-arc Additive Manufacturing expertise.

Metallic 3D printing firm Meltio has fashioned a strategic partnership with the French Navy to validate its Wire-Laser Directed Vitality Deposition (DED) additive manufacturing expertise for navy use. Following profitable assessments, together with a restore train for the Charles de Gaulle plane service, the French Navy plans to undertake Meltio’s system for onboard manufacturing and restore.

This partnership is important because it demonstrates the effectiveness of Meltio’s expertise in protection, following its earlier adoption by the Spanish Military and U.S. Navy. Based on the corporate, this collaboration goals to boost restore capabilities and operational effectivity throughout navy maneuvers.

Titomic has secured new buy orders value AUD$577k from a significant U.S. aerospace and protection firm, marking a major step in its multi-year qualification course of with the consumer. This collaboration goals to develop Titomic’s market presence within the U.S., enhancing its repute for assembly stringent trade requirements with modern manufacturing applied sciences.

Titomic says its collaboration highlights Titomic’s progress in offering chilly spray options for the aerospace and protection industries. The orders contribute to the corporate’s complete of AUD$8M in new orders since March 2024.

Development information from WASP and Ippolito Fleitz Group

3D printer producer WASP has launched its Crane WASP architectural 3D printing expertise to ESEB and ITS Academy Cantieri dell’Arte. This expertise might be built-in into the college’s coaching and analysis packages, permitting college students to discover sustainable functions within the development sector. Recognized for utilizing pure and standardized development supplies, the Crane WASP system goals to advertise sustainable improvement and develop using 3D printing within the Italian development trade.

Ippolito Fleitz Group and Aectual collaborated to create a 3D printed façade for the lately renovated BOSS retailer at İstinye Park in Istanbul. Produced from recycled supplies, the design displays a concentrate on sustainability and innovation, drawing inspiration from textile weaving patterns to align with the BOSS model.

Overlaying 73 sq. meters with 136 custom-printed panels, the façade offers each aesthetic worth and sensible capabilities, together with shading. Aectual’s Round Service permits for the panels to be recycled and repurposed into new merchandise after use.

Aerospace updates by Stratasys and ADS Group

3D printer OEM Stratasys and AM Craft have partnered to spice up the demand for flight-certified 3D printed elements within the aviation trade. This collaboration goals to handle the aviation sector’s provide chain challenges, notably in managing substitute elements for long-lived plane.

AM Craft’s EASA Half 21G Manufacturing Group Approval permits the manufacturing of licensed, airworthy 3D printed elements for airways and OEMs, says the corporate. By working with Stratasys, AM Craft goals to strengthen its world manufacturing community, develop its attain to Southeast Asia and past, and improve buyer confidence in 3D printing’s reliability in aviation.

ADS Group has supplied its 2024 Info and Figures report highlighting the numerous influence of the aerospace, protection, safety, and house sectors on the UK financial system, contributing £38.2 billion in 2023, a 50% improve over the past decade.

Employment in these industries has risen by 29% since 2013, reaching 427,500 jobs, with two-thirds based mostly outdoors of London. Exports have grown by 32%, amounting to £38.7 billion. These sectors present 42% larger productiveness than the UK common, underscoring their essential position in driving financial development and advancing manufacturing and protection capabilities.

Reseller offers from Farsoon Europe, HeyGears, and extra

Farsoon Europe has introduced a distribution partnership with MostTech, an Austrian supplier of 3D printing options. By this partnership, MostTech will distribute Farsoon’s industrial-grade steel and plastic additive manufacturing applied sciences, together with machines, supplies, and providers, throughout the Central European market.

With over three many years of expertise, MostTech is well-equipped to develop Farsoon’s attain, enhancing technical capabilities and offering superior, open 3D printing options. The partnership goals to raised serve native industries and elevate industrial additive manufacturing within the area.

Giant-format 3D printer producer BigRep has partnered with MakerPoint to develop its market attain throughout the BENELUX area, overlaying Belgium, the Netherlands, and Luxembourg. Doing so brings BigRep’s large-scale 3D printing options, together with a wide range of low- to high-temperature machines and supplies, to native producers.

By this partnership, industries within the area will acquire entry to in-house 3D printing expertise, enhancing manufacturing effectivity. With BigRep’s repute for big construct volumes and dependable machines, MakerPoint will now supply these options to fulfill the growing demand for additive manufacturing within the space.

3D printing startup Axtra3D has expanded its attain by partnering with Nota3D, now a full-access demo reseller for the Lumia X1 3D printer. This partnership strengthens Axtra3D’s potential to offer higher buyer assist and optimized 3D printing options. Molex has additionally adopted the Lumia X1 to boost its manufacturing capabilities, notably for growing prototypes and proof-of-concept functions.

Al Arend, Mannequin Store Supervisor from Molex, said, “The early outcomes we’re reaching utilizing this new expertise are spectacular. The piece half element is crisp and clear when working what are traditionally difficult supplies to print utilizing DLP expertise.”

Chinese language 3D printer producer HeyGears and PostProcess Applied sciences have partnered to boost 3D printing workflows for dental functions. HeyGears will distribute PostProcess’ full-stack post-processing options, together with {hardware}, software program, and chemistry, alongside its 3D printing techniques.

This partnership goals to enhance effectivity, security, and high quality in dental labs by streamlining resin removing and eliminating using isopropyl alcohol. By combining their experience, the collaboration will optimize digital dentistry workflows, enabling dental professionals to supply high-quality functions extra simply and safely.

Funding information from Fishy Filaments and AMARII

Fishy Filaments has exceeded its £100,000 Crowdcube funding goal with over per week to go. Initially aiming to boost £150,000, the profitable Alpha Powders trial, accomplished a number of months forward of schedule, lowered the speedy capital requirement.

The corporate, which turns end-of-life fishing nets into close to carbon-free nylon, is advancing its program to supply the world’s first 100% recycled powder for SLS 3D printing. This success might considerably rework its enterprise and assist cut back marine waste. Fishy Filaments plans to scale its operations globally with cell recycling vegetation.

Nationwide Heart for Protection Manufacturing and Machining’s (NCDMM) subsidiary AMARII is asking for superior manufacturing challenge proposals for its FY 2026 funding cycle. The main focus is on tasks that might profit Northeast Ohio’s financial system, notably these associated to additive manufacturing, automation, AI, power effectivity, and provide chain enhancement.

Precedence might be given to tasks that advance manufacturing applied sciences, promote job development, and improve competitiveness. AMARII has beforehand secured over $100 million in funding, emphasizing its success in supporting regional innovation, says the corporate.

Certifications and standardization information from 3D Programs and Aerosport Additive

3D printer producer 3D Programs’ Leuven, Belgium web site has acquired ISO ASTM 52920 certification, enhancing its potential to offer high-quality additive manufacturing (AM) options throughout sectors like aerospace, healthcare, protection, and semiconductor tools. Overlaying a variety of 3D printers and supplies, this certification reinforces the corporate’s dedication to assembly regulatory requirements and advancing its AM capabilities for complicated functions in regulated industries.

Additive manufacturing firm Aerosport Additive is celebrating the primary anniversary of its ISO 9001:2015 certification. Over the previous 12 months, the certification has helped the corporate improve belief with purchasers throughout numerous industries, together with automotive, medical, and aviation, by guaranteeing constant manufacturing requirements. Founder Geoff Combs famous that the certification has supported steady enhancements in processes and repair supply.

3D printing functions from CRP USA, Xover0, and extra

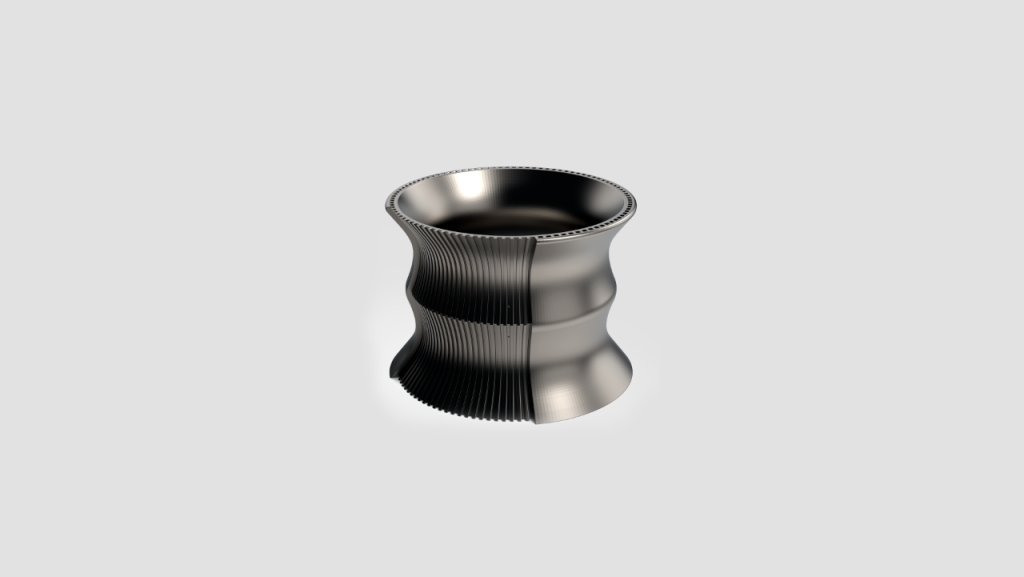

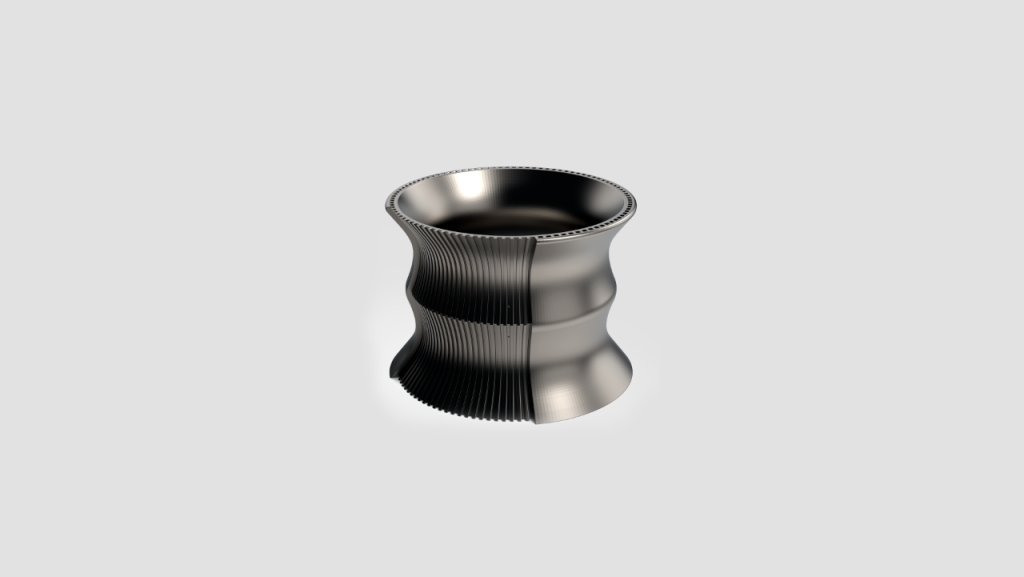

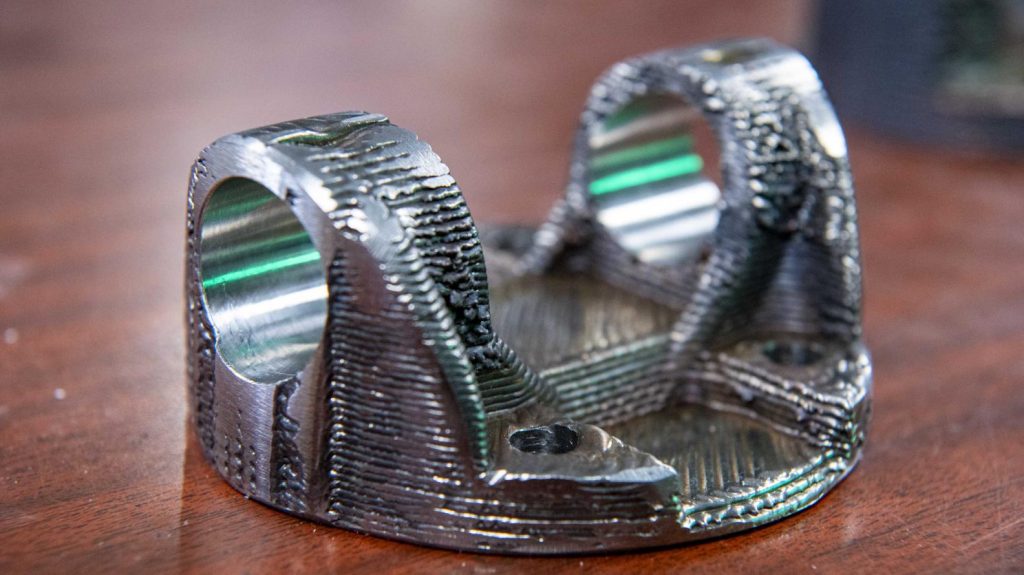

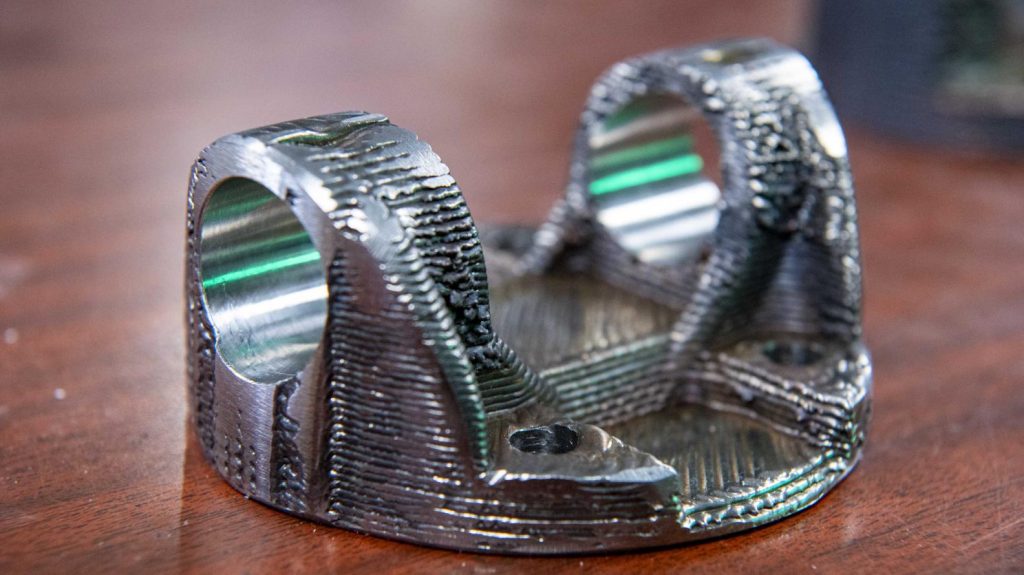

Yale College’s College of Engineering has launched a ceremonial mace designed by graduate Jacob Eldred, showcasing the development of engineering by means of numerous supplies and manufacturing methods.

The mace encompasses a base of hand-carved wooden, transitioning to brass, copper, aluminum, and chrome steel. A key part close to the highest, produced by Incus utilizing 3D printing expertise, demonstrates superior manufacturing capabilities with intricate geometries which can be tough to attain by means of conventional strategies.

CRP USA teamed up with Paralympic champion Tatyana McFadden to develop superior 3D printed wheelchair racing gloves. Using Selective Laser Sintering and Windform XT 2.0, the gloves supply superior energy, sturdiness, and lowered weight, considerably enhancing McFadden’s racing expertise. Designed to endure excessive friction and difficult situations, these gloves present each consolation and efficiency.

Xover0, a 3D printing jewellery studio specializing in intricate designs has introduced that its Geoheart necklace is featured within the newest Netflix movie Uglies, starring Joey King. Impressed by Artwork Deco structure, the pendant was chosen for its distinctive heart-shaped, ethereal design, complementing the futuristic aesthetic of the movie.

“It’s past thrilling,” stated co-founder Katherine Voorhies, one of many two design visionaries behind Xover0. “When Costume Designer Cris Araujo reached out to us we had been instantly excited by the chance. Cris has a formidable resume, so we knew our design was in good palms. And Joey King isn’t solely amazingly gifted as an actor, however she additionally has an uncanny eye for style. So it was a dream that they selected our Geoheart Pendant for such a outstanding position within the plot of Uglies.”

Regulation and regulatory information from 3D Labs and Stratasys

3D Lab has obtained patents in each the USA and China for its ultrasonic atomization expertise, which boosts the manufacturing of high-quality steel powders for additive manufacturing and different industrial makes use of.

The U.S. patent covers a technique and equipment for producing heavy steel powders, whereas the Chinese language patent focuses on the evacuation means of powders made by means of ultrasonic atomization. Each patents are key to the ATO collection, notably the ATO Lab Plus, a modular ultrasonic steel atomizer designed for laboratory-scale manufacturing. This expertise improves flowability, particle measurement management, and reduces oxygen content material, making it helpful for sectors similar to aerospace, automotive, medical units, and 3D printing.

In a Securities Change Fee (SEC) submitting kind 6-Ok Stratasys has introduced a $50 million share repurchase program, approved by its Board of Administrators, geared toward enhancing shareholder worth. This transfer aligns with Stratasys’ broader technique to enhance profitability and money circulation by driving income, aligning prices, and reinvesting in development.

Alongside the repurchase plan, the corporate is implementing a restructuring initiative anticipated to avoid wasting $40 million yearly by 2025, together with a 15% workforce discount. The repurchases might be tied to market situations, guaranteeing monetary flexibility for ongoing investments.

Software program updates from United Grinding Group and Quickparts

The UNITED GRINDING Group has adopted the umati interface to streamline knowledge integration from various machines, together with older fashions, in its manufacturing setting. By networking machines from numerous producers, like DMG Mori and WALDRICH COBURG, the group optimizes manufacturing effectivity and permits real-time monitoring. This challenge at STUDER demonstrates how umati modernizes older machines, contributing to the group’s objective of building a worldwide machine device communication commonplace.

Prototyping firm Quickparts has launched QuickQuote, a web based device that simplifies requests for quantity manufacturing in CNC machining, injection molding, and additive manufacturing. Prospects can simply submit challenge particulars and obtain personalized quotes.

The device helps large-scale manufacturing with a devoted challenge administration workforce. Quickparts offers complete providers, together with product lifecycle assist, world manufacturing capability, and strict high quality assurance, serving to prospects scale from prototyping to full manufacturing.

New analysis unveils strategies to strengthen AM supplies and improve efficiency

Engineers from the College of Glasgow’s James Watt College of Engineering and Polytechnic College of Marche in Italy have developed new insights into the deformation mechanisms that trigger 3D-printed supplies to fail below pressure. Their evaluation centered on polyetherimide (PEI) lattice buildings, revealing how defects, notably “interlayer injury,” weaken the fabric.

By growing an “enhancement issue” device, the workforce can now predict and decrease these defects, enhancing materials efficiency. The findings, printed in Superior Supplies Applied sciences, might result in stronger, lighter 3D-printed supplies for industries like aerospace and automotive, unlocking advantages in security and gas effectivity.

TRUMPF stories gross sales decline amid world financial challenges

German machine device producer TRUMPF the high-tech firm, reported a decline in each gross sales and order consumption for fiscal 12 months 2023/24. Gross sales decreased by 4% to €5.2 billion, whereas order consumption dropped by 10% to €4.6 billion. Regardless of a 4.5% improve in gross sales in Germany, making it TRUMPF’s largest marketplace for the primary time in years, gross sales fell by 12% within the U.S. and remained secure in China.

The corporate attributes this decline to the weak world financial system and ongoing geopolitical uncertainties, which have led to a noticeable discount in buyer investments. Regardless of these challenges, TRUMPF plans to counter the financial downturn with clear measures to enhance earnings.

AM Effectivity launches CCP-20 Megadrum for automated 3Dprint cleansing

AM Effectivity has unveiled the CCP-20 Megadrum, a machine designed to automate the cleansing course of for big 3D prints and huge print batches, suitable with SLS, MJF, and SAF applied sciences.

This resolution goals to streamline manufacturing, cut back power prices, and improve office ergonomics by eliminating the necessity for handbook dealing with. With a concentrate on Trade 4.0, the CCP-20 delivers constant, automated outcomes. Set for supply in September 2024, the system is predicted to pay for itself inside a 12 months, providing vital financial and operational benefits.

Specialists acknowledged for breakthroughs in AM at SFF symposium

Denis Cormier and Bey Vrancken have been acknowledged for his or her vital contributions to additive manufacturing on the Stable Freeform Fabrication Symposium (SFF). Cormier, from Rochester Institute of Know-how, acquired the FAME Award for his work in lattice buildings and molten steel droplet jetting.

Vrancken, from KU Leuven, was honored with the Jr FAME Award for his developments in warmth remedies, alloy design, and course of monitoring in laser powder mattress fusion. These awards spotlight their influence on the sector of 3D printing and manufacturing innovation.

What 3D printing traits do the trade leaders anticipate this 12 months?

What does the Way forward for 3D printing maintain for the following 10 years?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits 3D printed ceremonial mace. Photograph by way of Yale College.