The Supplies Processing Institute, a UK-based supplies analysis and innovation heart, is main a £600,000 analysis undertaking to allow better cost-efficiencies in metallic additive manufacturing by means of a novel synthetic intelligence (AI) device.

The UK-based analysis institute is collaborating with 3D printing SME Additive Manufacturing Options Ltd. (AMS) and additive manufacturing software program supplier AMFG to develop the AI-powered materials reuse administration device.

Known as SMART-APP, the device will provide predictive fashions for useful resource effectivity and waste discount administration in Laser Powder Mattress Fusion (LPBF) 3D printing.

SMART-APP is being developed to foretell high quality adjustments to metallic powder after 3D printing. The device will then suggest various course of parameters for the used powder, extending materials lifespan with restricted influence to half high quality.

It’s hoped that the SMART-APP will optimize powder reuse throughout LPBF 3D printing, making the method extra sustainable and cost-effective.

The analysis undertaking is being funded by Innovate UK, which is a part of the UK’s innovation company UK Analysis and Innovation (UKRI).

“SMART-APP is the subsequent logical step to proceed the work the Institute has already undertaken in powder characterisation. By growing a synthetic intelligence device that may assist AM customers create sooner and cheaper methods of maximizing powder reuse, the AM business, particularly these needing to maximise the operational effectiveness of their machines,” commented Nick Parry, Industrial Digitalisation Group Supervisor on the Supplies Processing Institute.

“This predictive device will develop and allow world class manufacturing of AM elements, with good options for useful resource effectivity and offering longer use of supplies feedstock and lowering wastage.”

Optimizing powder reuse with SMART-APP

Reusing metallic powder in 3D printing poses challenges. Most metallic powders are prone to floor oxidation, clustering, and porosity formations, which might hurt the mechanical properties of the 3D printed half. This has restricted powder reuse inside additive manufacturing, with medical and aerospace elements primarily being produced with virgin materials.

The £600,000 funding will allow the undertaking’s companions to conduct superior supplies characterization and mechanical testing. By means of this analysis, the workforce will examine the shelf life and processability of environmentally affected stainless-steel, titanium, and superalloy base LPBF feedstock.

The analysis workforce may also assess totally different strategies of reclaiming the used metallic powders, and the consequences this has on the ultimate product.

Outcomes will then be fed into a complicated database, which can correlate powder enter properties in opposition to 3D printed half efficiency with the assistance of AI. The ensuing predictive device might be made out there for business use.

“This initiative goals to rework additive manufacturing in the direction of extra resource-efficient strategies. SMART-APP goals to instill belief within the additive manufacturing realm by forecasting powder high quality and recommending processes to revive desired powder properties for reuse,” defined Alexander Grimmer, Technical Marketing consultant at AMFG.

In keeping with Grimmer, the event of the predictive SMART-APP will “expedite the widespread adoption of additive manufacturing,” and ship substantial environmental and financial advantages to the 3D printing business.

Rob Higham, CEO of Additive Manufacturing Options Ltd., added that this undertaking marks step one in the direction of reaching a “ground-breaking method for dynamic supplies administration.”

AI enhances metallic 3D printing

This isn’t the primary time AI has been leveraged to optimize metallic 3D printing.

Materialise, a worldwide chief in 3D printing software program and providers, gives its Course of Management software program for metallic 3D printing. This software program leverages AI to automate the metallic 3D printing high quality management course of, enabling notable time financial savings and price discount.

Materialise Course of Management analyzes and correlates layer knowledge in actual time through the 3D printing course of. This permits customers to find problematic elements earlier than post-processing and high quality inspection, which might add 30% to 70% to the price of making a component. What’s extra, early identification of scrap, and root trigger evaluation, helps to decrease prices by lowering materials waste and the variety of costly high quality management operations wanted after processing.

Elsewhere, Berlin-based software program firm 1000 Kelvin’s AMAIZE software program combines AI with physics and manufacturing knowledge to create optimum ‘recipes’ to make sure metallic elements are 3D printed accurately the primary time. Full business availability of AMAIZE was introduced at Formnext 2023.

As soon as a 3D print file is uploaded to the AMAIZE cloud, the AI software program analyzes the half and robotically addresses any thermo-mechanical points by optimizing scan technique and course of parameters. This streamlined method is alleged to scale back prices related to materials waste and power utilization.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You may as well observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of out there roles and kickstart your profession.

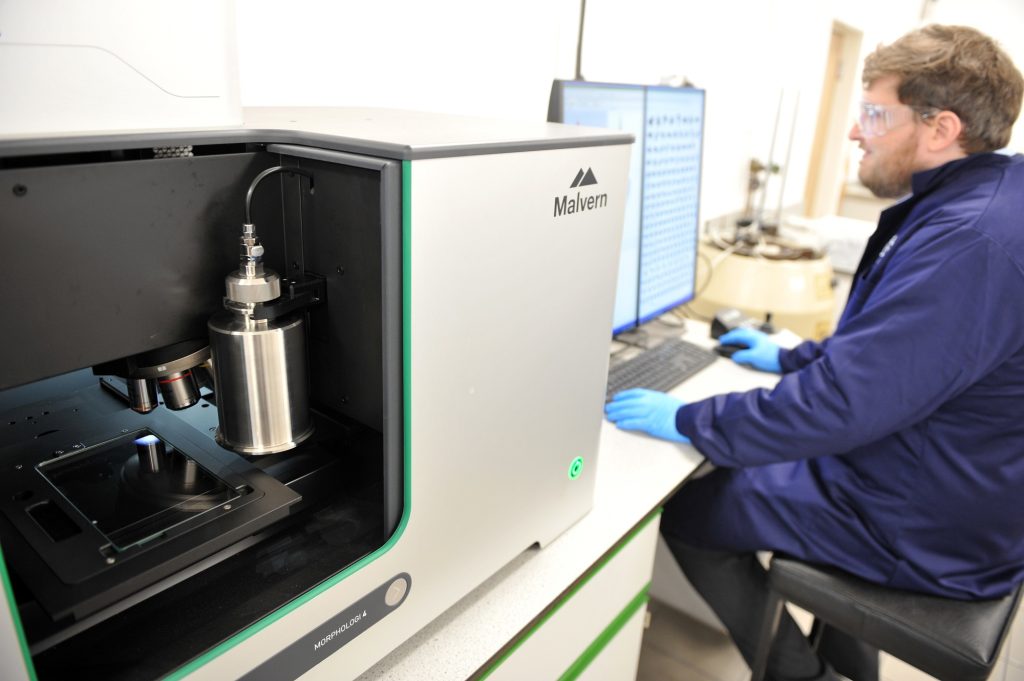

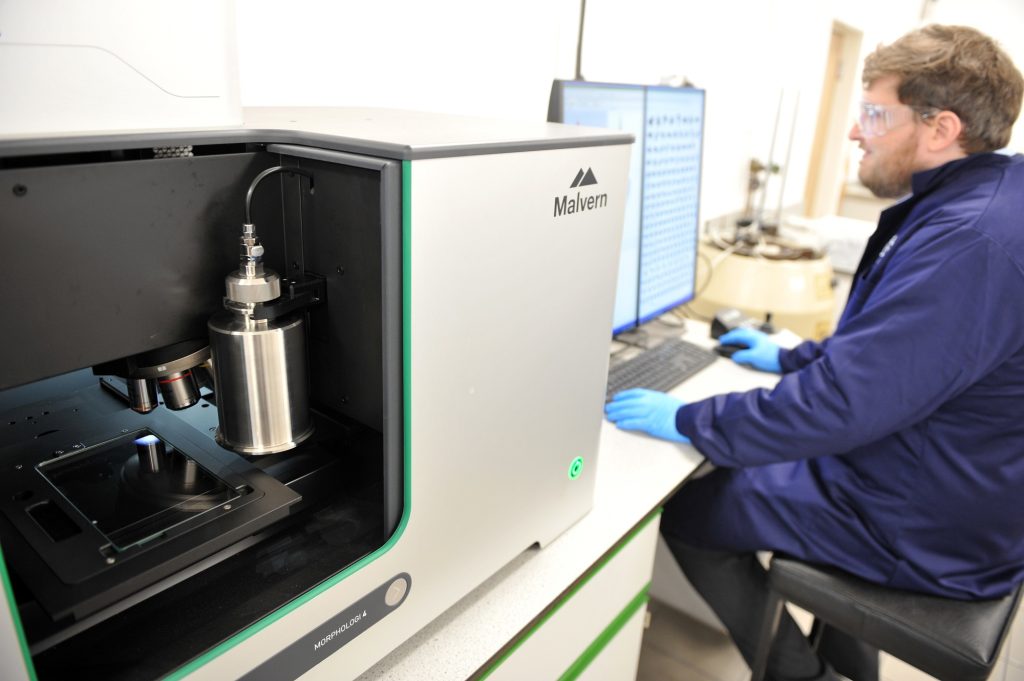

Featured picture exhibits powder evaluation utilizing morphological evaluation being carried out on the Supplies Processing Institute. Photograph by way of the Supplies Processing Institute.