6K Vitality, a division of superior materials specialist 6K, has signed a strategic provide settlement with steel recycling agency Aqua Metals.

By means of this partnership, the 2 corporations are working to ascertain a round materials provide chain for lithium-ion battery supplies, mentioned to be the primary of its form in North America.

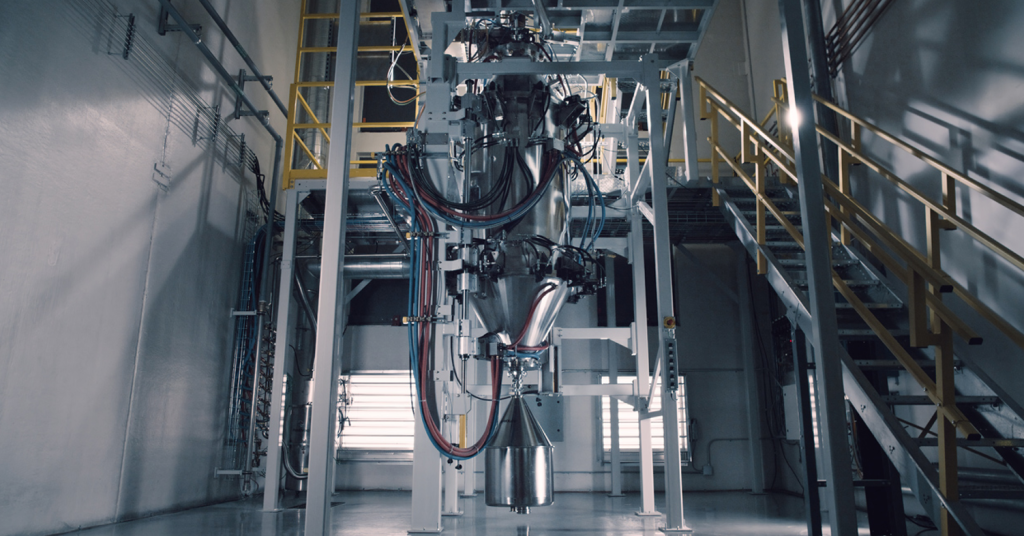

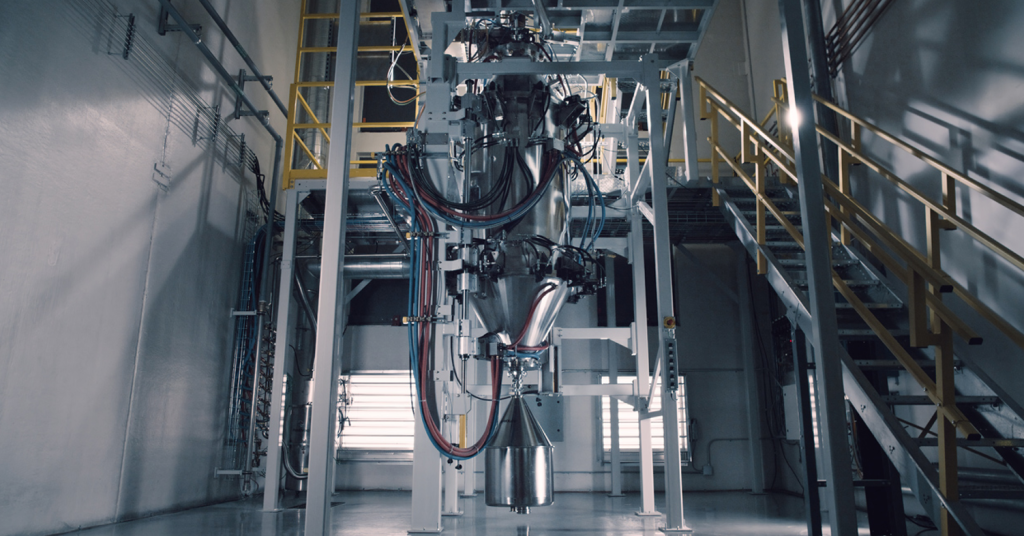

The settlement will see Aqua Metals provide 6K Vitality with recycled battery supplies from its Sierra ARC facility primarily based in Reno. Leveraging its proprietary UniMelt microwave plasma expertise, 6K will convert these important minerals into cathode lively supplies (CAM) at its PlusCAM manufacturing unit in Jackson, Tennessee.

The corporate will then promote the recycled CAM to home battery producers, creating a completely round US-based provide chain.

The settlement aligns with the US Authorities’s efforts to re-shore its manufacturing capabilities, amid world commerce challenges and elevated emphasis on environmental sustainability. By 2030, the lithium-ion battery manufacturing capability within the US is predicted to achieve almost one terawatt-hour.

As such, the partnership will qualify for home content material incentives underneath the Inflation Discount Act (IRA).

“This settlement extends past a provide contract; it’s a partnership geared toward redefining business requirements for environmental duty and cost-efficiency in battery materials manufacturing,” commented 6K Vitality President Sam Trinch.

“6K Vitality would be the first in North America to include giant portions of sustainably recycled metals into our superior battery supplies utilizing our low-cost, low-carbon footprint CAM manufacturing expertise.”

6K’s UniMelt expertise

6K Vitality claims that its UniMelt expertise can produce most supplies wanted for manufacturing lithium-ion batteries, together with NMC, LFP, LLZO, LNMO, LMO, LTO, and silicon anode.

Producing zero liquid or stable waste, UniMelt boasts a minimal carbon footprint. The expertise reportedly produces 70% much less greenhouse fuel emissions than different materials recycling processes.

In contrast to different multi-step strategies, UniMelt produces feedstock in a single closed-loop step. That is mentioned to decrease manufacturing course of occasions by 95%, translating to 50%-60% reductions in materials conversion prices.

Along with the manufacturing of lithium-ion battery supplies, UniMelt expertise can be closely deployed by 6K Additive, 6K’s 3D printing division, to supply 3D printable steel powders from scrap materials.

It was introduced final 12 months that 6K Additive had partnered with medical manufacturing agency Surgical Steel Recycling to recycle end-of-life surgical implants. Right here, UniMelt is used to transform the implant elements again into titanium powder, which may then be used to 3D print new implants.

Chatting with 3D Printing Trade at RAPID + TCT 2023 Leslie Frost, 6K Additive’s Senior Director of Advertising and marketing, said that this course of allows an “extremely sustainable and round provide chain.”

Elsewhere, 6K Additive has partnered with French industrial steel 3D printing specialist Z3DLab to supply its ZTi titanium alloys vary. Leveraging UniMelt expertise, 6K additive processes the ZTi alloys into spherical, dense powders optimized for additive manufacturing, reaching as much as 100% yield.

A US-based round provide chain for battery supplies

By means of the strategic provide settlement, which is able to start this 12 months, Aqua Metals has dedicated to offering 6K Vitality’s PlusCAM facility with 30% of the nickel and lithium carbonate it wants for CAM manufacturing.

This settlement will allow North American electrical car (EV) and lithium-ion battery producers to entry domestically produced cathode supplies which are inexpensive and possess a low-carbon footprint.

What’s extra, the collaboration seeks to deal with a rising demand for the recycling of producing scrap and end-of-life batteries, whereas decreasing reliance on minerals imported from abroad. Based mostly on present steel costs, the supplies equipped underneath this partnership may have an estimated worth of greater than $50 million as soon as each corporations’ amenities attain full capability.

“Our strategic settlement with 6K Vitality represents a pivotal second in our mission to construct a extra sustainable battery ecosystem from the bottom up right here in North America,” commented Steve Cotton, President and CEO of Aqua Metals.

“Collectively, we’re demonstrating the viability and financial advantages of closed-loop recycling for important battery metals and laying the muse for the US to say management on this quickly accelerating world business.”

Securing round provide chains

The emergence of world threats to imports, such because the COVID-19 pandemic, battle in Ukraine, and assaults on business delivery, has resulted within the elevated adoption of additive manufacturing to safe and re-shore round provide chains throughout the US. This adoption has additionally been pushed by efforts to develop extra environmentally sustainable manufacturing strategies.

Final 12 months, North Carolina-based titanium developer IperionX entered into an settlement to provide multinational automotive producer Ford with 100% recycled titanium. This settlement kinds elements of the 2 corporations’ ongoing collaboration to design, take a look at, and 3D print titanium elements for Ford Efficiency manufacturing automobiles.

The deal helps Ford’s efforts to scale back its carbon footprint, with the corporate committing to reaching carbon neutrality by 2050. Considerably, IperionX-produced titanium could be absolutely recycled on the finish of the product life-cycle, permitting for a completely round, low-carbon, and US-based automotive provide chain.

Final 12 months additionally noticed IperionX safe key improvement permits for its Tennessee-based Titan mission. Titan performs a key position in securing the US-based materials provide chains for titanium and uncommon earth minerals utilized in protection, EV, and renewable vitality functions. Finally, this mission performs a key position in reaching the corporate’s aim to create a completely round provide chain of titanium in North America.

Away from the US, a €5.6 million European Union (EU)-funded mission was not too long ago launched to advertise the remanufacturing and create a fully-circular home provide chain inside Europe. Known as CREDIT, the mission will develop a brand new AI-powered digital platform to help the remanufacturing course of and promote circularity of companies throughout the dwelling equipment, automotive, telecommunications, and aerospace industries.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information.

You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits the 6K Vitality PlusCAM manufacturing unit. Picture through 6K Vitality.