Warsaw-based 3D printing service bureau 3D Lab is introducing its ATO Suite at Formnext 2024.

Designed to supply researchers and producers with larger management over steel powder manufacturing, the ATO Suite permits the environment friendly and sustainable manufacturing of high-quality spherical steel powders from numerous feedstocks, catering to superior functions corresponding to additive manufacturing.

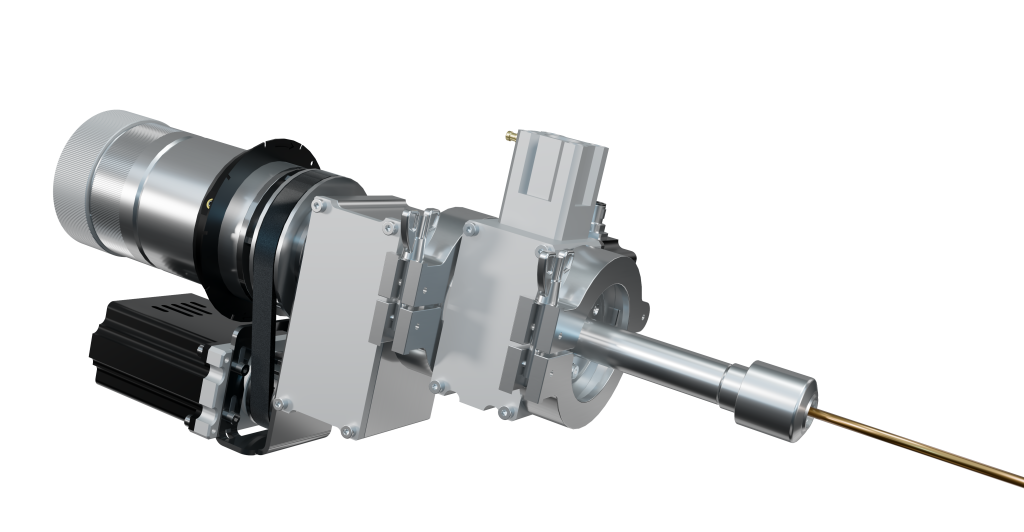

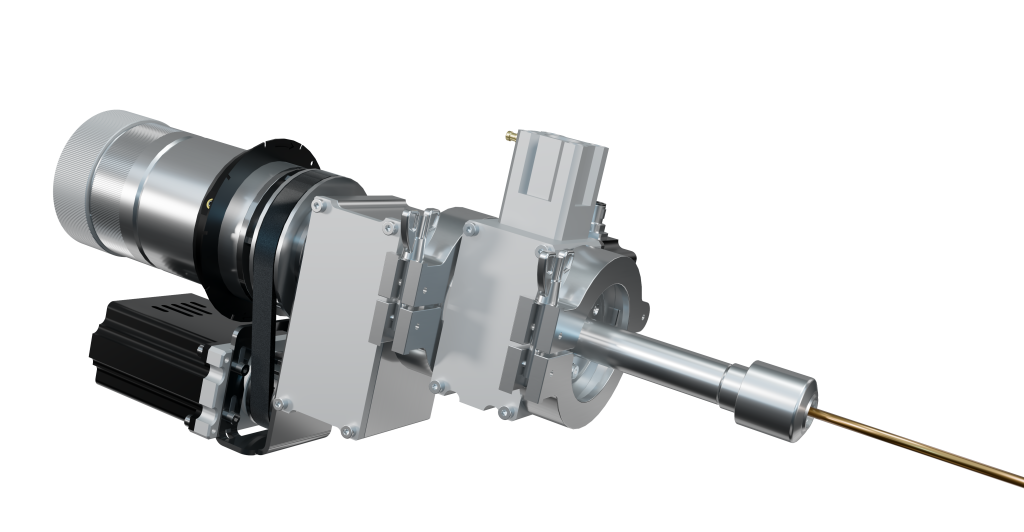

Comprising the ATO Lab Plus, ATO Noble, ATO Induction Melting System, ATO Solid, ATO Sieve, ATO Wipe, and ATO Clear, the ATO Suite is designed for seamless integration, even in space-constrained environments. Every element serves a selected objective, collectively addressing all the steel powder manufacturing workflow, from feedstock preparation to powder refinement and tools cleansing.

Reside demonstrations by 3D Lab in Corridor 11.0, Sales space B21, will showcase how the ATO Suite’s modular design and novel know-how allow producers to supply customized powders on demand whereas specializing in sustainability.

This launch builds on 3D Lab’s established experience in materials manufacturing and processing, marked by current milestones.

3D Lab’s powder manufacturing legacy

3D Lab lately secured patents for its ultrasonic atomization know-how within the U.S. and China, advancing the manufacturing of premium steel powders for AM and industrial use. Within the U.S., the patent addresses strategies and tools for producing heavy steel powders, whereas in China, it focuses on refining evacuation processes throughout atomization.

These patents assist the event of the ATO collection, with the ATO Lab Plus standing out as a modular resolution for laboratory-scale manufacturing. By enhancing powder flowability, making certain exact particle measurement management, and decreasing oxygen ranges, the know-how serves important industries corresponding to aerospace, automotive, healthcare, and 3D printing.

Constructing on its previous successes, 3D Lab partnered with jewellery producer Cooksongold in 2019 to create a compact atomizer particularly designed for valuable steel powder manufacturing. This collaboration led to the event of the ATO Noble, a compact atomizer using patented ultrasonic plasma atomization to optimize the dealing with of silver, platinum, and gold.

Advancing powder manufacturing effectivity and flexibility

On the core of the suite is the ATO Lab Plus, a lab-sized ultrasonic steel atomizer that gives on-demand powder manufacturing capabilities for reactive and non-reactive metals. Its small footprint and modular design cater to companies of all sizes, facilitating speedy alloy growth with exact particle measurement management. For industries working with high-value supplies, the ATO Noble atomizer can also be included incorporating a specialised filtration system to maximise materials restoration and high quality.

In the meantime, the ATO Induction Melting System (IMS) introduces a flexible resolution for processing numerous feedstocks, together with 3D printing scraps, into high-purity powders. By combining induction melting and ultrasonic atomization, IMS ensures flexibility, enabling producers to repurpose irregularly formed supplies whereas sustaining strict chemical purity requirements.

The ATO Solid vacuum casting furnace helps sustainable practices by enabling customers to recycle scraps and leftover powders into new rods for atomization. This reduces prices whereas selling a closed-loop materials stream for zero-waste manufacturing.

Enhancing workflow with complementary instruments

Different options inside the suite embrace the ATO Sieve, which ensures powder purity via ultrasonic sieving below inert fuel circumstances, and the ATO Wipe, an ultrasonic cleansing system for feedstock supplies corresponding to wires and rods. These instruments stop contamination and improve the standard of atomized powders. To make sure environment friendly transitions between supplies, the ATO Clear supplies hands-free cleansing of atomizer parts, minimizing downtime and the chance of cross-contamination.

To additional streamline operations, the Revolver Rod Feeding System permits the simultaneous atomization of as much as 10 rods, maximizing productiveness with exact management over feed velocity and rotation. Moreover, the ATO Distant Management pill permits real-time monitoring and adjustment of atomization processes, decreasing operator workload and enhancing effectivity.

A key spotlight of the ATO Suite is its potential to assist sustainable manufacturing via patented ultrasonic atomization know-how. Customers can recycle 3D printing scraps, outsized powders, and different waste supplies into high-quality steel powders, contributing to useful resource effectivity and decreasing reliance on exterior suppliers. This course of aligns with the trade’s rising emphasis on sustainability, making certain that innovation can coexist with environmental duty.

With its debut at Formnext 2024, the ATO Suite showcases 3D Lab’s method to sustainable and environment friendly steel powder manufacturing, providing researchers and producers sensible instruments for advancing their workflows.

Atone for all of the information from Formnext 2024.

Voting is now open for the 2024 3D Printing Trade Awards.

Wish to share insights on key trade developments and the way forward for 3D printing? Register now to be included within the 2025 3D Printing Trade Government Survey.

What 3D printing developments do the trade leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the following 10 years?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals the ATO Suite. Picture by way of 3D Lab.